-

Company

Product

ALUMINIUM MACHINES

PORTABLE MITER SAWS FOR ALUMINUM

PORTABLE COPY ROUTER MACHINES FOR ALUMINIUM

PORTABLE END MILLING MACHINES FOR ALUMINIUM

AUTOMATIC MITER SAWS FOR ALUMINIUM

COPY ROUTER MACHINES FOR ALUMINIUM

END MILLING MACHINES FOR ALUMINIUM

ALUMINUM CORNER CRIMPING MACHINE

DOUBLE MITRE SAWS FOR ALUMINIUM

AUTOMATIC SAWS FOR ALUMINIUM

BAR PROCESSING CENTERS

MACHINING CENTERS FOR ALUMINIUM COMPOSITE PANELS

NOTCHING SAWS

WEDGE CUTTING SAWS AND NOTCH CUTTING SAWS

MITER SAWS FOR ALUMINIUM

PVC PLASTIC MACHINES

PORTABLE MITER SAWS FOR PLASTIC

PORTABLE COPY ROUTER MACHINES FOR PLASTIC

PORTABLE END MILLING MACHINES FOR PLASTIC

MITER SAWS FOR PLASTIC

COPY ROUTERS FOR PLASTIC

END MILLING MACHINES FOR PLASTIC

WELDING MACHINES FOR PLASTIC

CORNER CLEANING MACHINES FOR PLASTIC PROFILES

DOUBLE MITRE SAWS FOR PLASTIC

BAR PROCESSING CENTERS

GLAZING BEAD SAWS

AUTOMATIC MITRE SAWS FOR PLASTIC

METAL MACHINES

MANUAL METAL SHEET BENDING MACHINE

MANUAL BENDING MACHINES

HYDRAULIC BENDING MACHINES

NON MANDREL BENDERS

PLATE BENDING MACHINES

BORDERING AND TRIMMING MACHINES

HORIZONTAL PRESSES

BELT GRINDING MACHINES

PIPE NOTCHING MACHINES

PIPE POLISHING MACHINES

LASER CUTTING MACHINES

PRESS BRAKES

VERTICAL TURNING CENTERS

MACHINING CENTERS

WOOD MACHINES

GLASS MACHINES

ROBOTICS SPECIAL MACHINERY

Service

Blog

Contact

Blog

- Home

- Blog

- BAR MACHINING CENTERS

- CNC MACHINING CENTERS FOR ALUMINIUM PROFILES IN THE AUTOMOTIVE INDUSTRY

CNC MACHINING CENTERS FOR ALUMINIUM PROFILES IN THE AUTOMOTIVE INDUSTRY

CNC Machining Centers for Aluminium Profiles in the Automotive Industry – Roof Racks, Body Reinforcements, Interior Structures, and EV Battery Housings

Introduction – Aluminium and the Future of the Automotive Industry

The automotive industry is undergoing a profound transformation. Lightweight design, electromobility, sustainability, and safety are the cornerstones of modern vehicle development. In this context, aluminium has become a key material.

With its properties – lightweight, strong, corrosion-resistant, and recyclable – aluminium is indispensable in today’s vehicle production. From roof racks and body reinforcements to interior structures and EV battery housings, aluminium profiles are essential elements of automotive lightweight design.

But these applications are only possible through precise machining. This is where CNC machining centers for aluminium profiles come into play. They allow the processing of complex profiles with maximum accuracy, high speed, and series production quality – a decisive factor for competitiveness in the automotive sector.

Why Aluminium in Automotive Manufacturing?

Aluminium is increasingly replacing steel and other materials in vehicle construction. Its advantages are clear:

-

Weight reduction – up to 40% lighter than steel → improved fuel efficiency and extended EV range.

-

High strength – lightweight yet capable of handling structural loads.

-

Corrosion resistance – reliable even under harsh conditions.

-

Recyclability – aluminium can be reused infinitely.

-

Design flexibility – complex cross-sections for body and interior applications.

-

Compatibility – suitable for hybrid structures with steel or carbon composites.

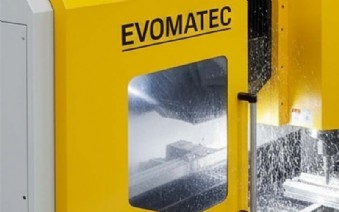

CNC Machining Centers – High-Tech for Automotive Manufacturing

A CNC machining center for aluminium profiles is a multifunctional production system designed to combine multiple machining processes in one machine. It is optimized for long profiles and complex geometries – perfect for automotive components.

Core Machining Functions:

-

Cutting & sawing – precise cutting of profile bars for automotive frames.

-

Milling – slots, recesses, drainage channels, and reinforcements.

-

Drilling & tapping – creating fastening points for screws and bolts.

-

Multi-side machining – 4- or 5-axis processing for complex shapes.

-

Copy milling – customized cut-outs for special automotive designs.

-

Automatic tool changing – efficient and fast transitions.

Technical Features of Modern Systems:

-

CNC control with CAD/CAM integration → direct implementation of design data.

-

Automatic profile feeders for serial production.

-

Clamping systems for profiles up to 8 meters.

-

Cooling and chip extraction systems for clean machining.

-

Robotic integration for fully automated production lines.

Applications in the Automotive Industry

1. Roof Racks

-

CNC-machined aluminium profiles form the base of roof racks and roof rails.

-

Advantages: lightweight, durable, corrosion-resistant.

-

Essential for cargo systems, roof boxes, and sporty vehicle designs.

2. Body Reinforcements

-

Reinforcement profiles improve the torsional rigidity of vehicles.

-

Applications include side impact protection, crash beams, and bumper structures.

-

CNC machining ensures precise fit and secure mounting points.

3. Interior Structures

-

Aluminium profiles serve as cockpit carriers, seat frames, and interior supports.

-

Advantages: low weight, high strength, easy assembly.

-

CNC machining centers deliver exact tolerances as specified by OEMs.

4. EV Battery Housings

-

One of the fastest-growing fields: battery housings for electric vehicles.

-

Requirements: strong, crash-resistant, corrosion-proof, and lightweight.

-

CNC machining allows the integration of cooling channels, reinforcements, and cable openings directly into the profile.

-

Result: safe, efficient, and durable battery enclosures.

Advantages of CNC Machining in Automotive Manufacturing

Precision and Series Quality

-

High repeatability even with millions of parts.

-

Perfect surfaces for both visible parts and safety-critical structures.

Increased Efficiency

-

All machining steps in one system → fewer setups, faster cycle times.

Automation

-

Seamless integration with robot handling and automatic loading systems → true 24/7 production.

Flexibility

-

Handles both standard profiles and custom complex geometries.

Sustainability

-

Reduced scrap, optimized material use.

-

Aluminium waste is fully recyclable in the closed-loop cycle.

The Future of CNC Machining Centers in Automotive Manufacturing

Automotive trends are reshaping machining technology:

-

Industry 4.0 – networked machines, real-time monitoring, predictive maintenance.

-

Electromobility – growing demand for precise EV battery housings and lightweight parts.

-

Batch size 1 – customized vehicle concepts with series efficiency.

-

Hybrid materials – machining aluminium alongside carbon composites and steel.

-

Sustainability – eco-friendly production with reduced CO₂ footprint.

Conclusion

A CNC machining center for aluminium profiles is an indispensable tool for modern automotive manufacturing.

From roof racks and body reinforcements to EV battery housings, the requirements of lightweight design, safety, and sustainability would be impossible to meet without advanced CNC machining.

Automotive OEMs and suppliers that invest in state-of-the-art aluminium machining centers position themselves as leaders in innovation, efficiency, and green mobility.

- CNC machining center aluminium profiles

- automotive aluminium profiles

- roof rack machining center

- body reinforcement aluminium machining

- aluminium profiles interior structures

- CNC machining EV battery housings

- aluminium machining center automotive industry

- EVOMATEC machines automotive

- lightweight aluminium profiles automotive

- bar machining center aluminium profiles

GERMANY

GERMANY ENGLISH

ENGLISH FRANCE

FRANCE SPAIN

SPAIN PORTUGAL

PORTUGAL