-

Company

Product

ALUMINIUM MACHINES

PORTABLE MITER SAWS FOR ALUMINUM

PORTABLE COPY ROUTER MACHINES FOR ALUMINIUM

PORTABLE END MILLING MACHINES FOR ALUMINIUM

AUTOMATIC MITER SAWS FOR ALUMINIUM

COPY ROUTER MACHINES FOR ALUMINIUM

END MILLING MACHINES FOR ALUMINIUM

ALUMINUM CORNER CRIMPING MACHINE

DOUBLE MITRE SAWS FOR ALUMINIUM

AUTOMATIC SAWS FOR ALUMINIUM

BAR PROCESSING CENTERS

MACHINING CENTERS FOR ALUMINIUM COMPOSITE PANELS

NOTCHING SAWS

WEDGE CUTTING SAWS AND NOTCH CUTTING SAWS

MITER SAWS FOR ALUMINIUM

PVC PLASTIC MACHINES

PORTABLE MITER SAWS FOR PLASTIC

PORTABLE COPY ROUTER MACHINES FOR PLASTIC

PORTABLE END MILLING MACHINES FOR PLASTIC

MITER SAWS FOR PLASTIC

COPY ROUTERS FOR PLASTIC

END MILLING MACHINES FOR PLASTIC

WELDING MACHINES FOR PLASTIC

CORNER CLEANING MACHINES FOR PLASTIC PROFILES

DOUBLE MITRE SAWS FOR PLASTIC

BAR PROCESSING CENTERS

GLAZING BEAD SAWS

AUTOMATIC MITRE SAWS FOR PLASTIC

METAL MACHINES

MANUAL METAL SHEET BENDING MACHINE

MANUAL BENDING MACHINES

HYDRAULIC BENDING MACHINES

NON MANDREL BENDERS

PLATE BENDING MACHINES

BORDERING AND TRIMMING MACHINES

HORIZONTAL PRESSES

BELT GRINDING MACHINES

PIPE NOTCHING MACHINES

PIPE POLISHING MACHINES

LASER CUTTING MACHINES

PRESS BRAKES

VERTICAL TURNING CENTERS

MACHINING CENTERS

WOOD MACHINES

GLASS MACHINES

ROBOTICS SPECIAL MACHINERY

Service

Blog

Contact

Blog

- Home

- Blog

- BAR MACHINING CENTERS

- CNC MACHINING

CNC MACHINING

Why CNC Machining Centers Are Not What You Think

Introduction

CNC machining centers are often misunderstood. Many assume they are nothing more than advanced milling machines, but in reality, they represent one of the most transformative innovations in modern manufacturing. Emerging from experimental numerical control systems in the 1940s and 1950s, today’s machining centers are powerful, versatile, and indispensable to global industry.

At their core, machining centers are computer-controlled, multi-functional machine tools designed to perform a wide range of operations with precision, efficiency, and minimal human intervention. Their defining feature is the integration of an automatic tool changer (ATC) and tool magazine, which enable seamless switching between multiple machining processes in a single setup. This versatility sets them apart from conventional CNC machines and explains why they are now considered essential equipment in manufacturing environments worldwide.

In this expert guide, we will clarify the misconceptions surrounding machining centers, examine their history and evolution, analyze their core components, and highlight their real-world applications across industries such as automotive, aerospace, and medical engineering.

What Is a CNC Machining Center?

CNC stands for Computer Numerical Control—the use of computer systems to automate the control of machine tools. This was a major evolution from early NC (Numerical Control) systems, which operated through punched tape instructions. The first NC machines appeared in the late 1940s, with the Cincinnati Milacron Hydrotel making history in 1952. By the 1970s, the advent of microprocessors had significantly reduced costs, ushering in a new era of precision manufacturing.

A CNC machining center differs from a basic CNC milling machine in one fundamental way: it incorporates an automatic tool changer supported by a tool magazine. This allows the system to complete multiple machining operations—milling, drilling, boring, tapping—without manual tool changes. In addition, machining centers often feature automatic chip conveyors, coolant management systems, and protective enclosures that improve both efficiency and operator safety.

Why the Term “Machining Center” Is Misunderstood

The confusion arises from the fact that many professionals casually use “CNC machine” and “machining center” interchangeably. While all machining centers are CNC machines, not all CNC machines qualify as machining centers. By definition, machining centers must include automatic tool changing and multi-process capabilities.

In contrast to the "plug-and-play" simplicity often associated with technologies like 3D printing, machining centers require sophisticated programming, setup, and operator expertise. They are not just “upgraded mills,” but fully automated production systems capable of handling complex geometries and workflows with exceptional precision.

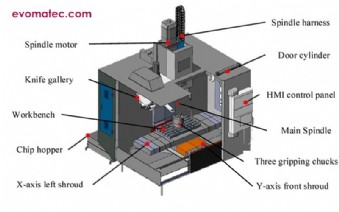

Core Components That Define Machining Centers

Several critical components elevate machining centers beyond standard CNC machines:

1. Main Spindle

The spindle is the heart of the machine, delivering rotational power for cutting operations. Available in vertical or horizontal orientations, modern spindles reach speeds up to 60,000 RPM, directly influencing precision, surface finish, and overall part quality.

2. Automatic Tool Changer (ATC)

This system rapidly swaps tools without operator intervention. In seconds, the ATC arm retrieves the current tool, replaces it with the next one from the magazine, and resumes cutting—minimizing downtime and boosting productivity.

3. Tool Magazine

Depending on the machine design, magazines may be carousel-, chain-, or hat-type, holding anywhere from 16 to over 100 tools. Arbitrary tool selection, controlled by coded commands, enables flexibility in complex manufacturing.

4. Automatic Pallet Changer (APC)

With pallet changers, operators can prepare the next workpiece externally while machining continues internally. Swing- or shuttle-type systems ensure continuous production, maximizing spindle uptime.

5. Chip and Coolant Management

High-pressure coolant delivery systems (up to 300 psi), programmable nozzles, and automatic chip conveyors maintain cutting accuracy, extend tool life, and protect machine components from contamination.

Types of CNC Machining Centers

Different machining center configurations exist to address specific production needs:

-

Vertical Machining Centers (VMCs)

Space-efficient with vertically mounted spindles, ideal for small to medium-sized parts. Typically offer lower spindle uptime (~25%). -

Horizontal Machining Centers (HMCs)

Spindles mounted parallel to the floor, allowing gravity-assisted chip removal. Deliver higher spindle uptime (~85%) and continuous productivity with pallet changers. -

Universal Machining Centers (UMCs)

Combine vertical and horizontal capabilities in one flexible platform. Highly versatile for multi-angle machining. -

5-Axis and Multi-Axis Machining Centers

Provide unmatched flexibility by allowing tools to approach the workpiece from virtually any angle. Ideal for aerospace and mold industries where complex, free-form geometries are standard.

How Machining Centers Are Actually Used

CNC machining centers integrate seamlessly with CAD/CAM software, which converts 3D models into G-code instructions that control the machine’s movements, tool paths, and speeds. This digital workflow enables:

-

Milling: Removing material to form shapes and contours.

-

Drilling & Boring: Creating and refining precise holes.

-

Tapping: Cutting threads into pre-drilled holes.

-

Multi-Axis Cutting: Producing complex surfaces in fewer setups.

This integration not only shortens production cycles but also ensures superior precision and repeatability.

Applications Across Industries

-

Automotive: Engine blocks, transmission housings, precision gears.

-

Aerospace: High-strength structural parts, turbine blades, lightweight alloys.

-

Medical: Implants, surgical tools, customized prosthetics.

-

Construction & Architecture: Aluminum profiles for windows, doors, curtain wall facades.

Conclusion

CNC machining centers are not just enhanced milling machines—they are fully integrated production systems. Their automatic tool changers, pallet systems, and chip management solutions create a dramatic leap in productivity and precision. With spindle uptimes as high as 85%, they far outperform basic CNC machines in both efficiency and consistency.

From vertical and horizontal configurations to 5-axis machining capabilities, these machines adapt to nearly every manufacturing requirement. Combined with CAD/CAM integration, they empower industries to prototype, iterate, and mass-produce with unprecedented accuracy.

The next time you see a perfectly engineered aerospace part, a flawless automotive component, or a custom medical implant, it is highly likely that a CNC machining center made it possible. These machines remain at the heart of modern manufacturing—and will continue to drive industrial progress for decades to come.

Key Takeaways

-

Machining centers differ from basic CNC machines by integrating automatic tool changers and tool magazines, enabling multiple operations in one setup.

-

Vertical, horizontal, universal, and 5-axis machining centers serve distinct applications.

-

Automation features such as APCs and chip management significantly increase productivity.

-

CAD/CAM integration streamlines workflows from design to final production.

-

Industries from automotive to aerospace and medical depend on machining centers for precision and reliability.

FAQs

Q1: What distinguishes a machining center from a standard CNC machine?

A machining center incorporates an automatic tool changer and magazine, enabling multiple automated operations, unlike basic CNC machines which require manual tool changes.

Q2: How do 5-axis machining centers improve manufacturing?

They reduce setups by allowing tools to approach parts from nearly any angle, enabling complex geometries—critical in aerospace and medical applications.

Q3: What advantages do horizontal machining centers offer?

They achieve higher spindle uptime (up to 85%), handle multiple surfaces in one setup, and feature pallet changers for uninterrupted operation.

Q4: Why is CAD/CAM integration important?

It translates digital designs directly into machine instructions, accelerating prototyping, ensuring consistency, and enabling complex part production.

Q5: Which industries rely most heavily on machining centers?

Automotive, aerospace, and medical sectors depend on machining centers for their ability to produce high-precision, safety-critical components.

- drilling

- 5 axis CNC

- aluminum machining

- precision manufacturing

- metalworking

- CNC technology

- CNC production

- CNC tolerance

- surface roughness

- CNC maintenance

- CNC prototyping

- CNC machining cost

- CNC cycle time

- CNC accuracy

- CNC grinding

- CNC drilling machine

- CNC machine tool

- multi axis machining

- CNC controller

- CNC components

- CNC parts manufacturing

- CNC automation

- Industry 4.0 CNC

- CNC operations

- CNC programming

- CNC production center

- CNC innovation

- machining processes

- metal cutting

- precision engineering

- high speed CNC

- CNC efficiency

- CNC applications

- CNC quality control

- CNC surface finishing

GERMANY

GERMANY ENGLISH

ENGLISH FRANCE

FRANCE SPAIN

SPAIN PORTUGAL

PORTUGAL