-

Company

Product

ALUMINIUM MACHINES

PORTABLE MITER SAWS FOR ALUMINUM

PORTABLE COPY ROUTER MACHINES FOR ALUMINIUM

PORTABLE END MILLING MACHINES FOR ALUMINIUM

AUTOMATIC MITER SAWS FOR ALUMINIUM

COPY ROUTER MACHINES FOR ALUMINIUM

END MILLING MACHINES FOR ALUMINIUM

ALUMINUM CORNER CRIMPING MACHINE

DOUBLE MITRE SAWS FOR ALUMINIUM

AUTOMATIC SAWS FOR ALUMINIUM

BAR PROCESSING CENTERS

MACHINING CENTERS FOR ALUMINIUM COMPOSITE PANELS

NOTCHING SAWS

WEDGE CUTTING SAWS AND NOTCH CUTTING SAWS

MITER SAWS FOR ALUMINIUM

PVC PLASTIC MACHINES

PORTABLE MITER SAWS FOR PLASTIC

PORTABLE COPY ROUTER MACHINES FOR PLASTIC

PORTABLE END MILLING MACHINES FOR PLASTIC

MITER SAWS FOR PLASTIC

COPY ROUTERS FOR PLASTIC

END MILLING MACHINES FOR PLASTIC

WELDING MACHINES FOR PLASTIC

CORNER CLEANING MACHINES FOR PLASTIC PROFILES

DOUBLE MITRE SAWS FOR PLASTIC

BAR PROCESSING CENTERS

GLAZING BEAD SAWS

AUTOMATIC MITRE SAWS FOR PLASTIC

METAL MACHINES

MANUAL METAL SHEET BENDING MACHINE

MANUAL BENDING MACHINES

HYDRAULIC BENDING MACHINES

NON MANDREL BENDERS

PLATE BENDING MACHINES

BORDERING AND TRIMMING MACHINES

HORIZONTAL PRESSES

BELT GRINDING MACHINES

PIPE NOTCHING MACHINES

PIPE POLISHING MACHINES

LASER CUTTING MACHINES

PRESS BRAKES

VERTICAL TURNING CENTERS

MACHINING CENTERS

WOOD MACHINES

GLASS MACHINES

ROBOTICS SPECIAL MACHINERY

Service

Blog

Contact

Blog

- Home

- Blog

- BAR MACHINING CENTER

- THE 5 AXIS MACHINING CENTER FOR ALUMINUM

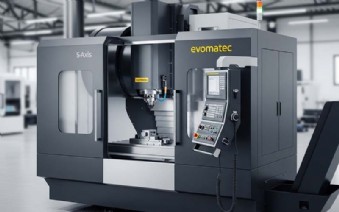

THE 5 AXIS MACHINING CENTER FOR ALUMINUM

The 5-Axis Machining Center for Aluminum: The Premier Class of Machining Technology

A 5-axis machining center for aluminum represents the absolute pinnacle of modern machining technology and is the key technology for manufacturing highly complex, precise, and geometrically demanding components. At a time when the lightweight material aluminum is opening up ever new design possibilities in key industries such as aerospace, automotive, and medical technology, these machines are indispensable for turning innovative designs into physical reality. Far more than a simple CNC milling machine, five-axis machining enables the complete manufacturing of workpieces with undercuts, free-form surfaces, and angled holes in a single setup. This leads to a dramatic increase in precision, efficiency, and geometric freedom. This comprehensive guide delves deep into the fascinating world of 5-axis machining of aluminum. We will illuminate in detail the complex technological foundations, the kinematics, the strategic advantages, the diverse application areas, and the economic aspects of this cutting-edge technology. The goal is to create a profound understanding of why the 5-axis machining center is the undisputed premier class of aluminum machining.

The Evolution into the Third Dimension: The Historical Development to the 5-Axis Machine

The journey from a simple, manually operated milling machine to an intelligent, fully automated 5-axis machining center is an impressive chronicle of technological progress, driven by the ever-increasing demands on component complexity.

The Beginnings: From Manual Control to 3-Axis CNC Machining

The first milling machines of the 19th century were purely mechanical apparatuses, whose precision depended entirely on the skill of the operator. The introduction of NC and later CNC technology in the mid-20th century revolutionized manufacturing. With the 3-axis machine, a tool could for the first time be moved by computer control in the three Cartesian spatial directions X, Y, and Z. This enabled the production of prismatic components with pockets, grooves, and holes with a previously unattainable repeatability. However, machining was limited to accessibility from one side. For operations on other sides, the workpiece had to be manually re-clamped—a time-consuming and error-prone process.

The Step to the 4th Axis: The Rotation of the Workpiece

The logical next step was the integration of a fourth axis, usually a rotational axis (A or B axis), on which the workpiece was clamped. This allowed a part to be machined from four sides without removing it from the clamping fixture. This was a huge step forward, especially in profile machining.

The Quantum Leap: The Conquest of the Fifth Axis

The true quantum leap to machining "without limits" was the addition of a fifth axis. This was done by implementing a second rotational axis. Now, the tool could be positioned at almost any angle to the workpiece. The driving force behind this development was, as is often the case in manufacturing technology, the aerospace industry. The production of aerodynamically optimized components such as impellers, blisks (Blade Integrated Disks), or complex structural components was not possible with 3- or 4-axis machines, or only with extremely high effort. 5-axis technology solved this problem and enabled the manufacturing of geometries that were previously considered "unmillable." Coupled with specialization in high-speed cutting (HSC) of aluminum, the modern 5-axis machining center as we know it today was born.

The Technology of Five Axes: Kinematics and Modes of Operation

The "five axes" are composed of the three familiar linear axes X, Y, and Z, as well as two additional rotational axes. Depending on which assembly of the machine—the table or the spindle head—performs these rotational movements, different machine kinematics are distinguished.

The Three Basic Linear Axes

-

X-axis: Represents the longitudinal movement, usually the longest travel axis of the machine.

-

Y-axis: Represents the transverse movement, perpendicular to the X-axis.

-

Z-axis: Represents the vertical movement or infeed axis, which controls the depth of cut.

The Two Rotary Swivel Axes

The two rotational axes are usually designated as A, B, and C:

-

A-axis: Rotation around the X-axis.

-

B-axis: Rotation around the Y-axis.

-

C-axis: Rotation around the Z-axis.

Common Machine Kinematics in Comparison

The way these five axes are realized in the machine has a major impact on dynamics, stability, and the ideal area of application.

Table-Side Kinematics: Trunnion Table

This is one of the most widespread designs, especially in small to medium-sized vertical machining centers.

-

Structure: The three linear axes are executed by the tool carrier (spindle). The two rotational axes (e.g., A and C axis or B and C axis) are realized by the machine table, which can both tilt and rotate.

-

Advantages: Very high stability and rigidity, as the pivot and rotation point is in the massive machine table. The workpiece is moved, the spindle remains stable in its orientation. Ideal for the high-precision manufacturing of smaller to medium-sized, complex components.

-

Disadvantages: The size and weight of the workpieces to be machined are limited, as the table must dynamically move the entire mass. The working area can be restricted by the swiveling movements of the table.

Head-Side Kinematics: Fork Head or Angle Head Spindle

In this design, the rotational movements are performed by the spindle head.

-

Structure: The machine table moves in the X and Y directions (or is fixed, as in gantry machines). The Z-axis is executed by the spindle head. The two rotational axes (e.g., A and C axis) are integrated directly into the spindle head (fork head).

-

Advantages: Ideal for machining very large and heavy workpieces, as the table only has to perform linear movements or stands completely still. The working area is very accessible and is not restricted by table movements.

-

Disadvantages: The protruding design of the fork head can be slightly inferior in dynamics and rigidity compared to table-side kinematics. Accessibility in narrow cavities can be limited by the head.

Mixed Kinematics

Here, the table and head share the rotational movements. For example, the table tilts around one axis (A-axis), while the spindle head rotates around the other axis (C-axis). This design attempts to combine the advantages of both concepts.

Our comprehensive expertise, based on countless successful customer installations, enables us to conduct every machine inspection with maximum meticulousness to guarantee both the highest quality standards and full compliance with CE safety regulations. The precise inspection and calibration of the rotational axes are of crucial importance for the accuracy of a 5-axis machine and a core point of our services.

Simultaneous Machining vs. 3+2 Positioning: Two Philosophies of 5-Axis Machining

The availability of five axes does not necessarily mean that all five must always move at the same time. Two basic strategies are distinguished.

3+2 Axis Machining (Positioned Milling)

This is the most common form of application for 5-axis technology.

-

Functionality: The two rotational axes are first used to bring the workpiece or the tool into a fixed, inclined position. The actual machining then takes place, as with a 3-axis machine, only with the linear axes X, Y, and Z.

-

Advantages:

-

Complete Machining: Enables 5-sided machining in a single setup, which drastically reduces setup times and increases accuracy, as errors from re-clamping are eliminated.

-

Use of Shorter Tools: By tilting, even deep cavities or hard-to-reach areas can be machined with shorter and thus more stable tools. This leads to better surfaces and higher material removal rates.

-

Simpler Programming: The NC programs are less complex than in simultaneous machining.

-

5-Axis Simultaneous Machining

Here, all five axes move simultaneously and coordinated during the machining process.

-

Functionality: The CNC control permanently calculates the position and orientation of all five axes to guide the tool along a complex 3D contour.

-

Application Areas:

-

Free-Form Surfaces: Essential for the production of aerodynamic surfaces, turbine blades, impellers, prostheses, or complex design surfaces in mold making.

-

Optimized Finishing Strategies: Even with prismatic components, simultaneous machining can be used to always keep the tool (e.g., a ball-nose cutter) at the optimal angle to the surface, thus creating perfect, transition-free surfaces.

-

-

Requirements: Places the highest demands on the dynamics of the machine, the computing power of the CNC control, and CAM programming.

The Technological Pillars of Aluminum 5-Axis Machining

To fully exploit the potential of 5-axis technology in aluminum machining, the entire system—machine, spindle, tool, and software—must be designed for high-speed cutting (HSC).

The HSC-Optimized Machine Structure

The machine must be extremely rigid and vibration-damping despite its complexity to absorb the high acceleration forces. A massive machine bed made of mineral casting or an FEM-optimized welded construction is the basis. Light but rigid moving components (e.g., the gantry or the vertical slide) are crucial for dynamics.

The High-Frequency Spindle

For aluminum, a high-frequency spindle (HF spindle) with speeds of 18,000 to over 30,000 RPM is essential. Only in this way can the necessary high cutting speeds be achieved, which ensure clean chip formation and low thermal load on the component. Powerful liquid cooling and high-quality ceramic bearings are mandatory for continuous operation at these speeds.

Intelligent Control Technology

The CNC control must have extremely high computing power.

-

Block Processing Time: The time the control needs to read a program block and convert it into machine movements must be in the millisecond range.

-

Look-Ahead Function: The control must be able to look ahead hundreds or thousands of program blocks to optimally plan speeds and accelerations over a long path and not have to slow down unnecessarily at corners or changes in curvature.

-

Special 5-Axis Functions: Features like "Tool Center Point Control" (TCPC) or dynamic collision monitoring are standard. TCPC ensures that the tool tip remains exactly on the programmed path even during swiveling movements of the head.

The CAD/CAM Process Chain

The programming of 5-axis simultaneous movements is done exclusively via powerful CAM systems. This software generates the complex toolpaths from the 3D CAD model.

-

HSC Strategies: The CAM system must master special strategies for HSC milling, such as trochoidal milling for roughing or spiral paths for finishing, to ensure a constant tool load.

-

Simulation: An integrated material removal and machine simulation is essential to check the complex movements in advance, safely avoid collisions with the workpiece, the fixture, or machine parts, and to optimize the process.

Based on our in-depth experience from numerous customer projects, we ensure that service and safety checks always meet the strictest criteria for quality and compliance with CE safety guidelines. This includes checking the software safety functions and the correct implementation of the machine simulation.

Industries and Application Examples: Where 5-Axis Technology is Indispensable

The ability to manufacture complex geometries in a single setup makes the 5-axis machining center a key machine in many high-tech industries.

Aerospace

This is the domain of 5-axis machining.

-

Structural Components (Ribs, Frames, Stringers): Monolithic manufacturing from large aluminum plates to maximize stability with minimum weight. 5-axis technology is necessary to mill the complex pockets and angled connection surfaces.

-

Impellers and Blisks: The curved blades of these turbine components can only be produced by 5-axis simultaneous milling.

-

Landing Gear Components: High-strength aluminum forgings are finished in 5 axes to meet the complex geometries and high accuracy requirements.

Automotive Industry and Motorsport

Here, too, lightweight construction drives the complexity of the components.

-

Prototype and Small Series Production: Cylinder heads, engine blocks, or gearbox housings can be milled directly from solid material to quickly obtain first prototypes for testing.

-

Mold Making: 5-axis machining of aluminum molds for the forming of body parts or for injection molds for plastic parts.

-

Motorsport: Manufacturing of aerodynamic attachments, extremely lightweight chassis components, or complex engine parts where every gram counts.

Medical Technology

The highest precision and the machining of biocompatible materials are paramount here.

-

Implants and Prostheses: Hip or knee joints individually adapted to the patient's anatomy from special alloys are milled on 5-axis machines.

-

Surgical Instruments: Complex instruments with organic shapes for minimally invasive surgery.

-

Housings for Medical Devices: Visually appealing and functionally complex housings for analysis or therapy devices.

Energy Technology and Mechanical Engineering

-

Turbine Housings: Large and complex housing parts for gas or steam turbines.

-

Hydraulic and Pneumatic Components: Control blocks with many intersecting, angled bores and channels.

-

Demanding Mechanical Engineering Parts: Any component that requires multiple machining steps on different angular planes is an ideal candidate for 5-axis complete machining.

Economic Viability: An Investment in a Leading Technological Position

Investing in a 5-axis machining center for aluminum is a strategic decision that sustainably enhances a company's technological capabilities.

Investment Costs

A 5-axis machining center is significantly more expensive to purchase than a comparable 3-axis machine. The complex mechanics of the rotational axes, the more sophisticated control technology, and the higher demands on machine accuracy drive up the price. In addition, there are higher costs for CAM software, employee training, and precise clamping and measuring tools.

The Unbeatable Benefit: Reduction of Total Costs

Despite the higher initial investment, 5-axis machining leads to a significant reduction in the total unit costs in the right applications.

-

Drastic Reduction of Setup Times: The biggest cost driver in single-part and small-series production is setup. Complete machining in a single setup eliminates up to four or five separate setup processes.

-

Increase in Accuracy: Every re-clamping of a workpiece carries the risk of inaccuracies. 5-axis machining eliminates this source of error and leads to significantly higher component accuracy.

-

Lower Tool Costs: By tilting the tool, shorter and thus more stable cutters can be used. These are less prone to vibration, produce better surfaces, and have a significantly longer service life.

-

Savings on Fixtures: Instead of building a separate, complex clamping fixture for each machining side, a simple basic clamping is often sufficient.

-

Opening Up New Business Fields: The ability to manufacture highly complex parts that competitors cannot offer secures a decisive market advantage and justifies higher prices.

The safety and longevity of systems is our top priority. That is why our many years of project experience are incorporated into every inspection to ensure first-class quality and consistent compliance with all CE safety standards. A correctly maintained and calibrated 5-axis machine is the basis for process-reliable and economical manufacturing.

Future Perspectives: The Autonomous and AI-Supported 5-Axis Center

The development of 5-axis technology is far from over. The future lies in further digitalization, automation, and intelligence of the systems.

Fully Automated Manufacturing Cells

The 5-axis machining center will become the core of fully automated cells. Pallet changers or robots will take over the loading and unloading of the machine. Integrated measuring systems will check the component quality directly in the machine and provide feedback to the control for automatic correction. Such cells can produce unmanned around the clock.

Artificial Intelligence (AI) in Process Control

AI algorithms will monitor and optimize the machining process in real time. Based on sensor data (vibrations, forces, temperatures), the machine will independently adjust its machining parameters (feed, speed) to always operate at the physical optimum. CAM programming will become easier as AI takes over many optimization tasks.

Hybrid Manufacturing

The combination of subtractive 5-axis milling with additive processes such as laser metal deposition in one machine will revolutionize manufacturing. This allows complex structures to be applied to simple raw parts or worn components to be repaired and then finished to final dimensions in 5 axes.

FAQ – Frequently Asked Questions about the 5-Axis Machining Center for Aluminum

Question 1: Is a 5-axis machine always better than a 3-axis machine?

Not necessarily. For purely prismatic components that only need to be machined from one side (e.g., simple plates), a 3-axis machine is often faster and more economical. The strength of the 5-axis machine lies in the complete machining of components that have multiple machining planes, inclined surfaces, or free-form contours. Here, it is unbeatable in terms of setup time, accuracy, and the geometric complexity it enables.

Question 2: What is "Tool Center Point" (TCP) and why is it so important in 5-axis machining?

The Tool Center Point is the center of the tool's cutting edge. The "Tool Center Point Control" (TCPC) function in the CNC control ensures that this point remains exactly on the programmed path, even when the rotational axes move and the spindle head swivels. Without TCPC, the tool tip would deviate from its path with every swiveling movement. The control calculates the necessary compensation movements of the linear axes in real time. This function is the basic prerequisite for precise 5-axis simultaneous machining.

Question 3: How complex is the programming of a 5-axis machine?

The programming, especially for 5-axis simultaneous machining, is significantly more complex than for a 3-axis machine and requires a powerful CAM system and well-trained programmers. The software must calculate collision-free toolpaths for all five axes simultaneously and take into account the exact kinematics of the specific machine. A thorough simulation of the process before starting the machine is therefore essential to avoid costly collisions.

Request a free consultation www.evomatec.com

- 5-axis machining center for aluminum

- 5-axis milling aluminum

- CNC 5-axis machining

- Aluminum machining

- Complete machining aluminum

- HSC milling 5-axis

- Free-form surface milling

- Simultaneous machining

- Aerospace machining

- Automotive prototyping

- Mold making aluminum

- Precision machining

- CNC machining center

- High-frequency spindle

- Machine tool kinematics

- CAD CAM 5-axis

- Tool Center Point Control

- Lightweight manufacturing

- Monolithic construction

- Fork head spindle

- Trunnion table

- Machining aluminum alloys

GERMANY

GERMANY ENGLISH

ENGLISH FRANCE

FRANCE SPAIN

SPAIN PORTUGAL

PORTUGAL