-

Company

Product

ALUMINIUM MACHINES

PORTABLE ALUMINIUM PROFILE MITRE SAW TOOL

PORTABLE COPY ROUTER MACHINE FOR ALUMINIUM PROFILES

PORTABLE END MILLING MACHINE FOR ALUMINIUM PROFILES

MITER SAW FOR ALUMINIUM PROFILES

COPY ROUTER MACHINE

END MILLING MACHINE FOR ALUMINIUM PROFILES

AUTOMATIC HYDRAULIC ALUMINIUM PROFILE CORNER CRIMPING MACHINE

DOUBLE HEAD CUTTING MACHINE FOR ALUMINIUM PROFILES

CNC AUTOMATIC SAW MACHINE FOR ALUMINIUM PROFILES

CNC PROFILE MACHINING CENTRES

ALUMINIUM COMPOSITE PANEL PROCESSING MACHINES

NOTCHING SAW MACHINE

WEDGE CUT SAW AND CLEAT CUT SAW

PVC PLASTIC MACHINES

PVC PLASTIC PROFILE MITER SAW MACHINE

PORTABLE COPY ROUTER MACHINE FOR PVC PLASTIC PROFILES

PORTABLE END MILLING MACHINE FOR PVC PLASTIC PROFILES

MITER SAW MACHINE FOR CUTTING PVC PLASTIC PROFILES

COPY ROUTER MACHINE FOR PVC PLASTIC PROFILE

END MILLING MACHINE FOR PVC PLASTIC PROFILES

PVC PLASTIC WELDING MACHINE

CORNER CLEANING MACHINE FOR PVC PLASTIC PROFILES

DOUBLE HEAD CUTTİNG MACHINE FOR PVC PLASTIC PROFILES

PROFILE MACHINING CENTRES

GLASS BEAD SAW

PRECISION MITER SAW FOR PLASTIC PROFILES

METAL MACHINES

MANUAL METAL SHEET BENDING MACHINE

MANUAL BENDING MACHINE

HYDRAULIC BENDING MACHINES

NON MANDREL BENDERS

PLATE BENDING MACHINES

BORDERING AND TRIMMING MACHINES

HORIZONTAL PRESSES

BELT GRINDING MACHINES

PIPE NOTCHING MACHINES

PIPE POLISHING MACHINES

LASER CUTTING MACHINES

CNC HYDRAULIC PRESS BRAKES MACHINE

CNC VERTICAL TURNING CENTER

CNC MACHINING CENTER

WOOD MACHINES

GLASS MACHINES

ROBOTICS SPECIAL MACHINERY

Service

Blog

Contact

product

- Home

- product

- METAL MACHINES

- MANUAL METAL SHEET BENDING MACHINE

- CNC MACHINING CENTER EVO FZ5

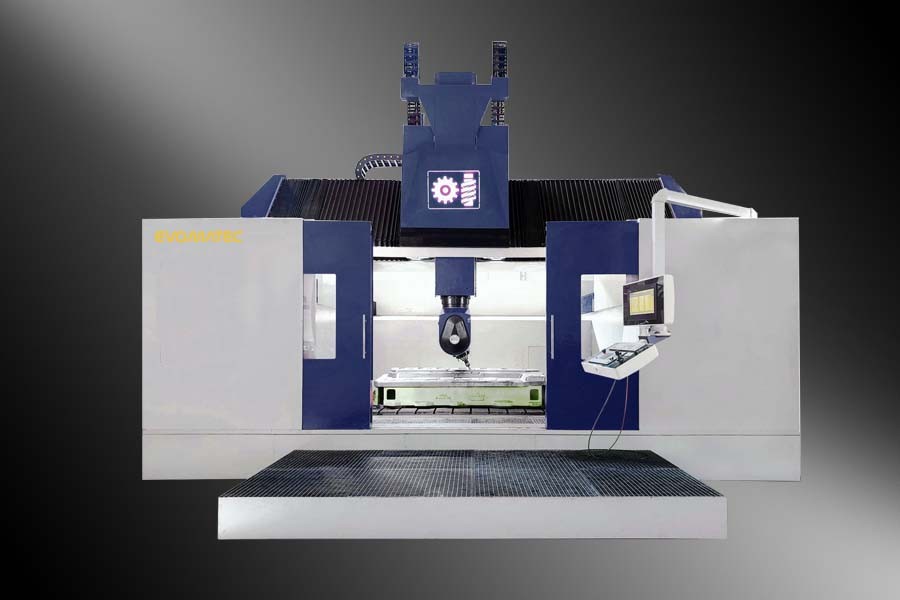

5 Axis Monoblock Milling Machine

The Evomatec Machine Tool EVO FR 3500 is engineered with precision and crafted entirely from GG30 cast iron, sourced from our proprietary foundry. The castings undergo a stress-relieving heat treatment, ensuring optimal structural integrity and performance. The body components are precisely machined on advanced milling equipment, and the surfaces for linear guide mounting are meticulously ground for unparalleled accuracy.

Key Features:

Monoblock Cast Iron Body Design: Constructed from a single block of GG30 cast iron, the IGM FR 3500 offers exceptional rigidity and eliminates the need for heavy-duty foundation work. This innovative design contributes to enhanced machine stability and reduced vibrations during operation.

Advanced Cooling System: All axes are equipped with water-cooling systems that operate in critical areas where dynamic components are located. This cooling mechanism is designed to minimize thermal distortion during axis movements, particularly when handling heavy components, ensuring high-precision machining. The special casting technique is patent-protected.

Precision Measurement and Assembly: The machine components are carefully measured and assembled using state-of-the-art tools, including the Renishaw Laser Interferometer, Niveltronic precision devices with Bluetooth communication, Atos 3D Scanner, and certified granite gauge blocks, ensuring the highest standards of accuracy.

High-Performance Axis Drive Systems: The drive systems are composed of high-quality linear guideways, servo motors, gear units, and rack-and-pinion gear systems, all chosen for their performance and reliability. Each axis is equipped with absolute measuring scales for precise position feedback.

Top-Tier Components: Every kinematic, pneumatic, hydraulic, electrical, and electronic component is sourced from leading brands to guarantee the utmost quality and reliability, ensuring the long-term performance and durability of the machine.

Monoblock Design for Stability and Accuracy: The monoblock design significantly contributes to the machine’s high stability and accuracy. All aspects of the design undergo dynamic, static, stress, vibration, and fatigue analyses using finite element methods to ensure the highest engineering standards and optimized production planning.

High-Speed Machining Head: Equipped with a fork-type machining head, capable of reaching 16,000 rpm and delivering up to 220 Nm of torque, ensuring precise and high-speed machining for various applications.

Compliance with International Standards: The machine adheres to CE, VDI-DGQ 3441, and ISO standards for accuracy, performance, and safety, ensuring it meets industry norms and customer requirements.

EVO FR 3500

- X Axis Stroke (mm): 2500

- Y Axis Stroke (mm): 3500

- Z Axis Stroke (mm): 1400

- A Axis Rotation (°): ± 115

- C Axis Rotation (°): ± 360

- Rapid Feedrate (m/min):

- X: 30

- Y: 30

- Z: 30

- Spindle Speed (rpm): 12500

- Spindle Power (kW) - S1: 54

- Spindle Torque (Nm) - S1: 200

- Spindle Torque (Nm) - S6: 235

- Tooling Taper Type: HSK-A100

- Positioning Accuracy (mm): 0,012

- Repeatability Accuracy (mm): 0,010

- Table Load (kg/m²): 4000

- Machine Size (mm):

- X: 7800

- Y: 7370

- Z: 6600

- Machine Weight (kg): 70000

EVO FR 3500 XL

- X Axis Stroke (mm): 6500

- Y Axis Stroke (mm): 3500

- Z Axis Stroke (mm): 1400

- A Axis Rotation (°): ± 115

- C Axis Rotation (°): ± 360

- Rapid Feedrate (m/min):

- X: 30

- Y: 30

- Z: 30

- Spindle Speed (rpm): 12500

- Spindle Power (kW) - S1: 54

- Spindle Torque (Nm) - S1: 200

- Spindle Torque (Nm) - S6: 235

- Tooling Taper Type: HSK-A100

- Positioning Accuracy (mm): 0,012

- Repeatability Accuracy (mm): 0,010

- Table Load (kg/m²): 4000

- Machine Size (mm):

- X: 11500

- Y: 7400

- Z: 6600

- Machine Weight (kg): 120000

EVO FR 3500 XXL

- X Axis Stroke (mm): 10500

- Y Axis Stroke (mm): 3500

- Z Axis Stroke (mm): 2350

- A Axis Rotation (°): ± 115

- C Axis Rotation (°): ± 360

- Rapid Feedrate (m/min):

- X: 30

- Y: 30

- Z: 30

- Spindle Speed (rpm): 12500

- Spindle Power (kW) - S1: 54

- Spindle Torque (Nm) - S1: 200

- Spindle Torque (Nm) - S6: 235

- Tooling Taper Type: HSK-A100

- Positioning Accuracy (mm): 0,012

- Repeatability Accuracy (mm): 0,010

- Table Load (kg/m²): 4000

- Machine Size (mm):

- X: 16000

- Y: 7400

- Z: 8500

- Machine Weight (kg): 195000

TAGS

- CNC milling machine

- CNC milling for steel

- CNC milling for iron

- metal CNC milling machine

- steel machining CNC

- iron machining CNC

- CNC milling metal

- high precision CNC milling

- CNC milling for metal

- steel CNC machining

- iron CNC machining

- CNC milling center steel

- CNC milling center iron

- CNC metal milling

- industrial CNC milling machine

- precise CNC milling machine

- CNC milling steel parts

- iron milling CNC

GERMANY

GERMANY ENGLISH

ENGLISH FRANCE

FRANCE SPAIN

SPAIN PORTUGAL

PORTUGAL