-

Company

Product

ALUMINIUM MACHINES

PORTABLE ALUMINIUM PROFILE MITRE SAW TOOL

PORTABLE COPY ROUTER MACHINE FOR ALUMINIUM PROFILES

PORTABLE END MILLING MACHINE FOR ALUMINIUM PROFILES

MITER SAW FOR ALUMINIUM PROFILES

COPY ROUTER MACHINE

END MILLING MACHINE FOR ALUMINIUM PROFILES

AUTOMATIC HYDRAULIC ALUMINIUM PROFILE CORNER CRIMPING MACHINE

DOUBLE HEAD CUTTING MACHINE FOR ALUMINIUM PROFILES

CNC AUTOMATIC SAW MACHINE FOR ALUMINIUM PROFILES

CNC PROFILE MACHINING CENTRES

ALUMINIUM COMPOSITE PANEL PROCESSING MACHINES

NOTCHING SAW MACHINE

WEDGE CUT SAW AND CLEAT CUT SAW

PVC PLASTIC MACHINES

PVC PLASTIC PROFILE MITER SAW MACHINE

PORTABLE COPY ROUTER MACHINE FOR PVC PLASTIC PROFILES

PORTABLE END MILLING MACHINE FOR PVC PLASTIC PROFILES

MITER SAW MACHINE FOR CUTTING PVC PLASTIC PROFILES

COPY ROUTER MACHINE FOR PVC PLASTIC PROFILE

END MILLING MACHINE FOR PVC PLASTIC PROFILES

PVC PLASTIC WELDING MACHINE

CORNER CLEANING MACHINE FOR PVC PLASTIC PROFILES

DOUBLE HEAD CUTTİNG MACHINE FOR PVC PLASTIC PROFILES

PROFILE MACHINING CENTRES

GLASS BEAD SAW

PRECISION MITER SAW FOR PLASTIC PROFILES

METAL MACHINES

MANUAL METAL SHEET BENDING MACHINE

MANUAL BENDING MACHINE

HYDRAULIC BENDING MACHINES

NON MANDREL BENDERS

PLATE BENDING MACHINES

BORDERING AND TRIMMING MACHINES

HORIZONTAL PRESSES

BELT GRINDING MACHINES

PIPE NOTCHING MACHINES

PIPE POLISHING MACHINES

LASER CUTTING MACHINES

CNC HYDRAULIC PRESS BRAKES MACHINE

CNC VERTICAL TURNING CENTER

CNC MACHINING CENTER

WOOD MACHINES

GLASS MACHINES

ROBOTICS SPECIAL MACHINERY

Service

Blog

Contact

product

- Home

- product

- METAL MACHINES

- MANUAL METAL SHEET BENDING MACHINE

- CNC VERTICAL TURNING CENTER EVO VDZ

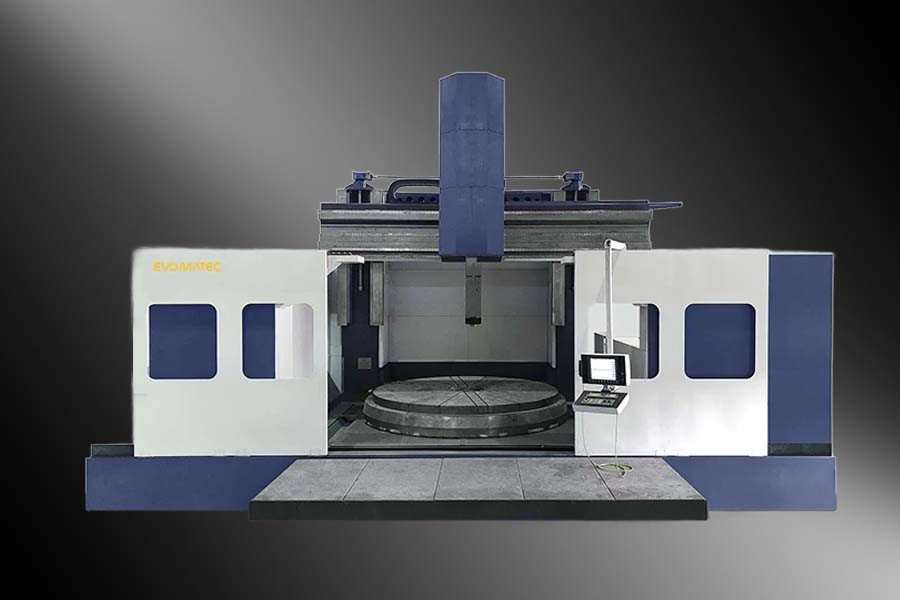

CNC Vertical Lathe Machine with Ø4000 mm Hydrostatic Rotary Table & Moving Traverse

A high-precision CNC vertical turning center, engineered to the highest German technology and quality standards for machining large and heavy workpieces. The direct-driven, hydrostatically guided rotary table with C-axis functionality ensures maximum stability, precision, and durability. Thanks to the moving traverse and a high-performance motor spindle, turning, milling, drilling, and grinding can be performed with exceptional accuracy. This machine combines German engineering excellence with state-of-the-art CNC technology to deliver maximum productivity and precision.

Key Features:

Hydrostatically guided rotary table with high-precision C-axis

High-performance motor spindle for milling, drilling, and grinding

Moving traverse for flexible machining of large workpieces

Maximum workpiece load: 40,000 kg

Key Specifications:

Table Diameter: 4000 mm

Max. Turning Diameter: 5000 mm

Max. Turning Height from Table: 2000 mm

Ram Slide Stroke: 2100 mm

Ram Section: 350 x 350 mm

Vertical Travel of Moving Traverse: 2000 mm

Table Performance:

Table Drive System: Segmented Direct Drive Motors

Table Torque (Nominal): 8200 Nm

Table Torque (Max): 14400 Nm

Table Speed: 60 rpm

Table Workload: 40,000 kg

Table Guide System: Hydrostatic Bearing & Guides

Spindle Characteristics:

Spindle Speed: 4000 rpm

Spindle Power: 37 kW

Spindle Torque: 1200 Nm

Tooling Taper Type: ISO 50

Machine Dimensions:

Machine X Size: 7500 mm

Machine Y Size: 12000 mm

Machine Z Size: 9500 mm

Machine Weight: 125,000 kg

TAGS

- CNC vertical lathe

- vertical turning center

- vertical lathe machine

- CNC vertical turning lathe

- buy CNC vertical lathe

- vertical lathe manufacturer

- high-precision vertical lathe

- industrial vertical lathe

- hydrostatic rotary table

- CNC lathe with C-axis

- vertical lathe with moving traverse

- high-precision CNC lathe

- direct-drive rotary table

- motor spindle vertical lathe

- heavy-duty lathe

- vertical lathe for large workpieces

- vertical lathe for heavy workpieces

- milling drilling grinding with CNC lathe

- high-performance vertical lathe

- CNC lathe for aerospace

- CNC lathe for space industry

- CNC lathe for mechanical engineering

- CNC lathe for large parts

GERMANY

GERMANY ENGLISH

ENGLISH FRANCE

FRANCE SPAIN

SPAIN PORTUGAL

PORTUGAL