-

Company

Product

ALUMINIUM MACHINES

PORTABLE MITER SAWS FOR ALUMINUM

PORTABLE COPY ROUTER MACHINES FOR ALUMINIUM

PORTABLE END MILLING MACHINES FOR ALUMINIUM

AUTOMATIC MITER SAWS FOR ALUMINIUM

COPY ROUTER MACHINES FOR ALUMINIUM

END MILLING MACHINES FOR ALUMINIUM

ALUMINUM CORNER CRIMPING MACHINE

DOUBLE MITRE SAWS FOR ALUMINIUM

AUTOMATIC SAWS FOR ALUMINIUM

BAR PROCESSING CENTERS

MACHINING CENTERS FOR ALUMINIUM COMPOSITE PANELS

NOTCHING SAWS

WEDGE CUTTING SAWS AND NOTCH CUTTING SAWS

MITER SAWS FOR ALUMINIUM

PVC PLASTIC MACHINES

PORTABLE MITER SAWS FOR PLASTIC

PORTABLE COPY ROUTER MACHINES FOR PLASTIC

PORTABLE END MILLING MACHINES FOR PLASTIC

MITER SAWS FOR PLASTIC

COPY ROUTERS FOR PLASTIC

END MILLING MACHINES FOR PLASTIC

WELDING MACHINES FOR PLASTIC

CORNER CLEANING MACHINES FOR PLASTIC PROFILES

DOUBLE MITRE SAWS FOR PLASTIC

BAR PROCESSING CENTERS

GLAZING BEAD SAWS

AUTOMATIC MITRE SAWS FOR PLASTIC

METAL MACHINES

MANUAL METAL SHEET BENDING MACHINE

MANUAL BENDING MACHINES

HYDRAULIC BENDING MACHINES

NON MANDREL BENDERS

PLATE BENDING MACHINES

BORDERING AND TRIMMING MACHINES

HORIZONTAL PRESSES

BELT GRINDING MACHINES

PIPE NOTCHING MACHINES

PIPE POLISHING MACHINES

LASER CUTTING MACHINES

PRESS BRAKES

VERTICAL TURNING CENTERS

MACHINING CENTERS

WOOD MACHINES

GLASS MACHINES

ROBOTICS SPECIAL MACHINERY

Service

Blog

Contact

product

- Home

- product

- METAL MACHINES

- MANUAL METAL SHEET BENDING MACHINE

- TUBE NOTCH MILLING MACHINE EVO TT 140

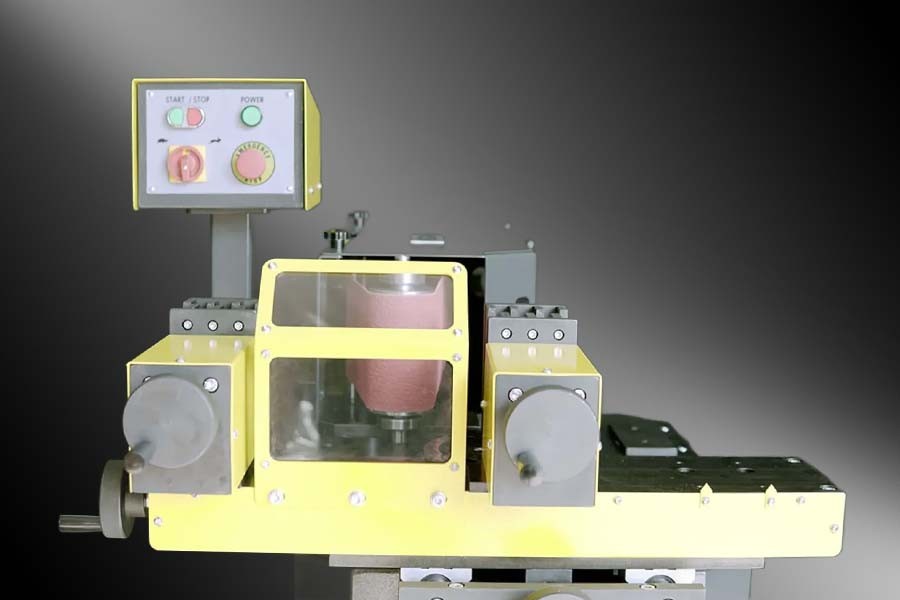

EVO TT 140 tube notch milling machine – Precision for Steel, Stainless Steel and Aluminium

The EVO TT 140 tube notching machine is the ideal solution for precise notching, coping and fitting of metal tubes and profiles made of steel, stainless steel or aluminium. Whether in railing construction, tube frame manufacturing, vehicle building or general metalworking – this machine ensures perfectly fitting tube joints and greatly simplifies weld preparation.

With its robust construction, high-precision bearing system and adjustable front rollers, the EVO TT 140 is suitable for both series production and custom projects. The swivelling vise enables notching at angles of up to 50°, while the horizontal movement of the machine body allows precise grooving along the tube or profile surface.

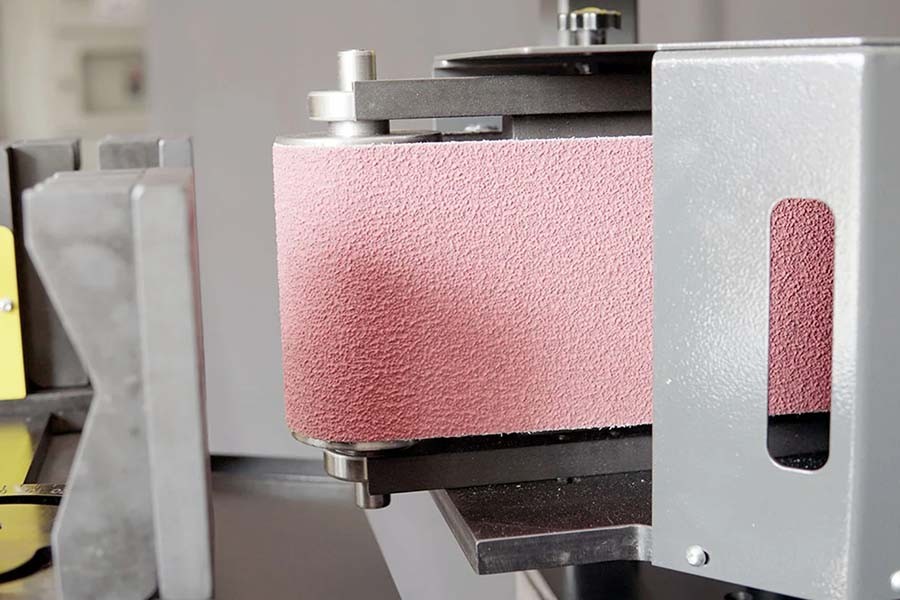

The quick clamping system ensures fast and secure workpiece fixation, and the easy belt change minimises downtime. This machine covers a wide range of applications and is also known in the industry as a tube kerbing machine, tube notch grinder or tube end milling machine.

Technical Highlights / Standard Equipment

-

Flexible diameter adjustment: Notching of profiles and tubes of various diameters with adjustable front rollers

-

Angle processing up to 50°: Accurate notching with swivelling vise

-

Quick belt change: Easy and time-saving abrasive belt replacement

-

Horizontal grooving: Grooving along the tube/profile surface via horizontal movement of the machine body

-

Versatile vise movement: Right, left, forward and backward movement on a precision bearing system

Your Benefits

-

Precise notching for perfect weld joints

-

High flexibility through adjustable rollers and swivelling vise

-

Time-saving operation with quick clamping and belt change

-

Robust construction for industrial use

-

Versatile application for steel, stainless steel and aluminium

TAGS

- tube notch milling machine

- tube notching machine

- tube kerbing machine

- tube notch grinder

- tube end milling machine

- metal tube notching

- profile tube notching

- weld preparation tubes

- 50 degree notching machine

- horizontal tube grooving

- stainless steel tube notching

- aluminium tube notching

- steel tube notching

- tube processing machine

- tube end preparation

- industrial tube notcher

- precision tube notching

GERMANY

GERMANY ENGLISH

ENGLISH FRANCE

FRANCE SPAIN

SPAIN PORTUGAL

PORTUGAL