-

Company

Product

ALUMINIUM MACHINES

PORTABLE MITER SAWS FOR ALUMINUM

PORTABLE COPY ROUTER MACHINES FOR ALUMINIUM

PORTABLE END MILLING MACHINES FOR ALUMINIUM

AUTOMATIC MITER SAWS FOR ALUMINIUM

COPY ROUTER MACHINES FOR ALUMINIUM

END MILLING MACHINES FOR ALUMINIUM

ALUMINUM CORNER CRIMPING MACHINE

DOUBLE MITRE SAWS FOR ALUMINIUM

AUTOMATIC SAWS FOR ALUMINIUM

BAR PROCESSING CENTERS

MACHINING CENTERS FOR ALUMINIUM COMPOSITE PANELS

NOTCHING SAWS

WEDGE CUTTING SAWS AND NOTCH CUTTING SAWS

MITER SAWS FOR ALUMINIUM

PVC PLASTIC MACHINES

PORTABLE MITER SAWS FOR PLASTIC

PORTABLE COPY ROUTER MACHINES FOR PLASTIC

PORTABLE END MILLING MACHINES FOR PLASTIC

MITER SAWS FOR PLASTIC

COPY ROUTERS FOR PLASTIC

END MILLING MACHINES FOR PLASTIC

WELDING MACHINES FOR PLASTIC

CORNER CLEANING MACHINES FOR PLASTIC PROFILES

DOUBLE MITRE SAWS FOR PLASTIC

BAR PROCESSING CENTERS

GLAZING BEAD SAWS

AUTOMATIC MITRE SAWS FOR PLASTIC

METAL MACHINES

MANUAL METAL SHEET BENDING MACHINE

MANUAL BENDING MACHINES

HYDRAULIC BENDING MACHINES

NON MANDREL BENDERS

PLATE BENDING MACHINES

BORDERING AND TRIMMING MACHINES

HORIZONTAL PRESSES

BELT GRINDING MACHINES

PIPE NOTCHING MACHINES

PIPE POLISHING MACHINES

LASER CUTTING MACHINES

PRESS BRAKES

VERTICAL TURNING CENTERS

MACHINING CENTERS

WOOD MACHINES

GLASS MACHINES

ROBOTICS SPECIAL MACHINERY

Service

Blog

Contact

product

- Home

- product

- PVC PLASTIC MACHINES

- PORTABLE MITER SAWS FOR PLASTIC

- AUTOMATIC DOUBLE MITER SAW EVOG X

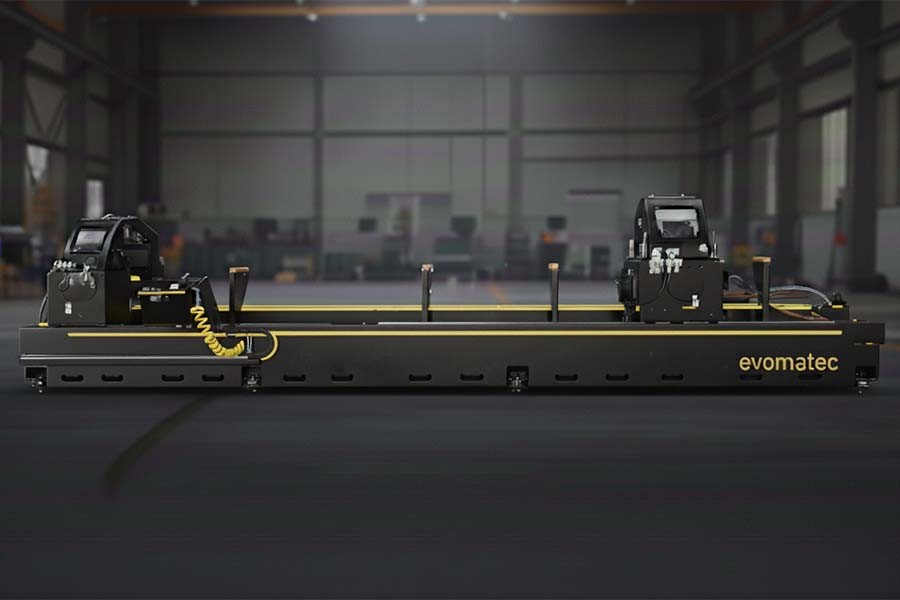

Automatic Double Miter Saw for PVC, Plastic, and Window Profiles EVOG X

Maximum Precision and Industrial Performance in Plastic Profile Cutting

The automatic double miter saw EVOG X by Evomatec has been specifically designed for precise cutting and mitering of PVC and plastic profiles used in modern window and door manufacturing.

With state-of-the-art servo technology, automatic 3-axis control, and a cutting length of up to 6000 mm, it provides the perfect solution for production facilities that require accurate, fast, and clean cuts with maximum efficiency.

Thanks to its hydro-pneumatic feed system and robust mechanical construction, the EVOG X ensures vibration-free, repeatable, and perfectly angled cuts — ideal for PVC profiles, sashes, frames, mullions, and other plastic components used in profile manufacturing.

Technical Innovation for PVC and Plastic Profiles

The EVOG X combines servo-driven accuracy, digital control, and energy-efficient drive technology in one of the most advanced double miter saws in its class.

It has been engineered specifically for thermoplastic materials — including PVC, ABS, PMMA, polycarbonate, and similar plastics — delivering clean, burr-free cuts without deformation or material stress.

Technical Specifications of the EVOG X

-

Saw blades: 2 × Ø 550 mm, carbide-tipped (HM)

-

Motor power: 2 × 3 kW (4 HP)

-

Cutting length: min. 460 mm – max. 6000 mm

-

Angle adjustment: servo-controlled 30° – 90°

-

Feed system: hydro-pneumatically controlled

-

Positioning speed: 40 m/min

-

Air pressure: 6 – 8 bar | consumption 150 L/min

-

Total power: 9.1 kW | 400 V | 50–60 Hz

-

Machine weight: approx. 2240 kg

Equipment and Control System

The EVOG X double miter saw for PVC profiles is designed for maximum user comfort, safety, and precision cutting in industrial applications.

Standard Equipment

-

Servo-driven rotating axes with automatic head positioning

-

Digital angle control (30° – 90°)

-

Pneumatic clamping cylinders (horizontal + vertical)

-

Spray-cooling system for PVC and plastic profiles

-

Heavy-duty roller table for long profile support

-

Electronic feed and cutting speed regulation

-

CE-certified protective covers

-

Intuitive 10″ touchscreen control panel

-

Ethernet and USB ports for data transfer

-

Compatibility with chip extraction and PVC waste systems

Optional Equipment

-

EVOSOFT – integrated cutting optimization software to minimize material waste

-

Barcode printer for production tracking and identification

-

Additional support arms for extra-long window profiles

-

Automatic chip extraction with integrated filter unit

Advantages of the EVOG X Double Miter Saw

1. Precision and Repeatability in PVC and Plastic Cutting

Servo-driven head movements ensure absolute dimensional accuracy with every cut.

Whether cutting window frames, sash profiles, or plastic casings, each part is produced with exact, repeatable angles.

2. Large Cutting Capacity up to 6 Meters

With a maximum cutting length of 6000 mm, the EVOG X is ideal for long PVC window and door profiles as well as large structural components.

3. Perfect Cutting Quality – No Reworking Needed

The combination of hydro-pneumatic feed control and spray-cooling delivers smooth, burr-free cut surfaces without thermal damage — ensuring flawless welds in PVC window production.

4. Robust Construction – Low Maintenance and Long Lifespan

Its cast-steel base guarantees stability and vibration-free operation, while premium drive units and precision bearings provide long-term reliability with minimal maintenance requirements.

5. User-Friendly Digital Control

Through the 10-inch touchscreen, operators can easily control cutting angles, head positions, and feed speeds — fast, intuitive, and precise.

This makes the machine ideal for automated production lines.

6. Safety and Energy Efficiency

All components comply with European CE safety standards.

Servo motors only activate when required, reducing energy consumption by up to 25 %.

Applications

The EVOG X was developed specifically for industrial PVC and plastic profile fabrication and is suitable for a wide range of applications:

-

Window manufacturing: precise miters for frames and sash profiles

-

Door production: accurate 45° cuts for jambs and door frames

-

Facade and conservatory construction: cutting structural PVC profiles

-

General profile processing: PVC, plastic, polycarbonate, ABS, acrylic

Its speed, repeatability, and material protection make the EVOG X the ideal solution for series production and industrial profile processing.

Evomatec Quality and Future-Oriented Design

The EVOG X double miter saw represents German engineering excellence, advanced servo control, and industrial reliability.

Each unit is CE-certified, electrically tested, and mechanically calibrated before delivery to ensure consistent quality.

Integration into digital production environments (Industry 4.0), combined with Ethernet / USB data communication and the EVOSOFT cutting optimization system, makes the EVOG X a truly future-ready machine for PVC profile processing.

Evomatec provides global technical service and spare-parts support through more than 270 international service centers, ensuring maximum uptime and efficiency for every customer.

Conclusion – The Future of PVC Profile Cutting

The EVOG X automatic double miter saw for PVC, plastic, and window profiles unites servo precision, digital control, and industrial efficiency in one high-performance system.

It is the ideal choice for manufacturers who demand high production output, exact angles, and long-term reliability in PVC window and door profile fabrication.

Contact our sales team: info@evomatec.de

Request a free consultation: https://evomatec.de/en/contact/

TAGS

- Double miter saw PVC

- double miter saw plastic

- double miter saw window profiles

- double miter saw door profiles

- servo double miter saw PVC

- hydro-pneumatic miter saw plastic

- automatic double miter saw PVC

- EVOG X

- double head miter saw PVC

- miter saw for window production

- miter saw for door manufacturing

- CNC double miter saw plastic

- PVC profile processing machine

- plastic profile cutting machine

- servo controlled miter saw PVC

- CE certified miter saw plastic

- EVOSOFT cutting optimization system

- industrial PVC miter saw

- Evomatec double miter saw PVC

- miter saw for plastic window profiles

GERMANY

GERMANY ENGLISH

ENGLISH FRANCE

FRANCE SPAIN

SPAIN PORTUGAL

PORTUGAL