-

Company

Product

ALUMINIUM MACHINES

PORTABLE MITER SAWS FOR ALUMINUM

PORTABLE COPY ROUTER MACHINES FOR ALUMINIUM

PORTABLE END MILLING MACHINES FOR ALUMINIUM

AUTOMATIC MITER SAWS FOR ALUMINIUM

COPY ROUTER MACHINES FOR ALUMINIUM

END MILLING MACHINES FOR ALUMINIUM

ALUMINUM CORNER CRIMPING MACHINE

DOUBLE MITRE SAWS FOR ALUMINIUM

AUTOMATIC SAWS FOR ALUMINIUM

BAR PROCESSING CENTERS

MACHINING CENTERS FOR ALUMINIUM COMPOSITE PANELS

NOTCHING SAWS

WEDGE CUTTING SAWS AND NOTCH CUTTING SAWS

MITER SAWS FOR ALUMINIUM

PVC PLASTIC MACHINES

PORTABLE MITER SAWS FOR PLASTIC

PORTABLE COPY ROUTER MACHINES FOR PLASTIC

PORTABLE END MILLING MACHINES FOR PLASTIC

MITER SAWS FOR PLASTIC

COPY ROUTERS FOR PLASTIC

END MILLING MACHINES FOR PLASTIC

WELDING MACHINES FOR PLASTIC

CORNER CLEANING MACHINES FOR PLASTIC PROFILES

DOUBLE MITRE SAWS FOR PLASTIC

BAR PROCESSING CENTERS

GLAZING BEAD SAWS

AUTOMATIC MITRE SAWS FOR PLASTIC

METAL MACHINES

MANUAL METAL SHEET BENDING MACHINE

MANUAL BENDING MACHINES

HYDRAULIC BENDING MACHINES

NON MANDREL BENDERS

PLATE BENDING MACHINES

BORDERING AND TRIMMING MACHINES

HORIZONTAL PRESSES

BELT GRINDING MACHINES

PIPE NOTCHING MACHINES

PIPE POLISHING MACHINES

LASER CUTTING MACHINES

PRESS BRAKES

VERTICAL TURNING CENTERS

MACHINING CENTERS

WOOD MACHINES

GLASS MACHINES

ROBOTICS SPECIAL MACHINERY

Service

Blog

Contact

product

- Home

- product

- PVC PLASTIC MACHINES

- PORTABLE MITER SAWS FOR PLASTIC

- DOUBLE MITER SAW FOR PLASTIC PROFILES EVOG VSA

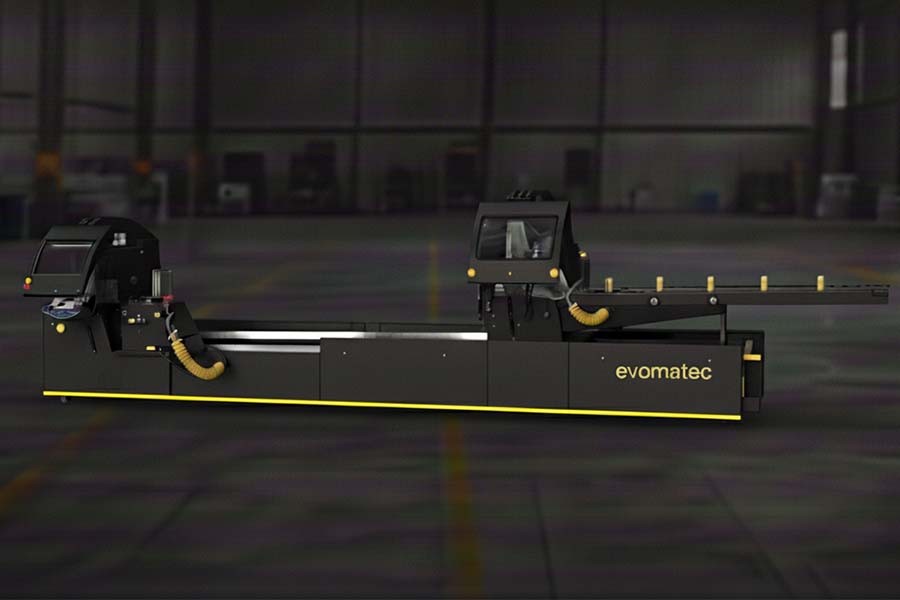

Double Miter Saw for Plastic Profiles EVOG VSA

The Double Miter Saw for Plastic Profiles EVOG VSA by Evomatec represents a new generation of industrial cutting technology designed for high-precision processing of PVC and plastic profiles.

Developed for the accurate miter cutting of profile ends, it delivers exceptional precision, repeatability, and efficiency for the modern production of windows, doors, and façades made of plastic and composite materials.

Equipped with servo-driven positioning, automatic head control, and hydro-pneumatic feed technology, the EVOG VSA combines industrial strength, speed, and ease of operation.

Its versatile angle adjustment system enables accurate and consistent cuts on a wide variety of plastic and PVC profile geometries.

Automatic Precision for Plastic and PVC Profiles

In the manufacturing of PVC windows and doors, the precision of each miter cut determines the tightness, alignment, and finish quality of the final product.

The EVOG VSA Double Miter Saw for Plastic Profiles has been engineered to achieve exactly that: clean, burr-free, and smooth cuts, even on thin-walled or complex profile sections.

Its servo-controlled positioning system allows automatic head movement between –22.5°, –45°, 90°, and +45°, while intermediate angles can be adjusted manually with precision.

This flexibility makes the EVOG VSA ideal for both high-volume production and custom manufacturing applications.

Technical Features of the EVOG VSA

The EVOG VSA is built for durability, accuracy, and user convenience — perfect for heavy-duty industrial use in continuous operation.

Technical specifications:

-

Saw blades: Ø 550 mm, tungsten carbide-tipped (TCT)

-

Motor power: 2 × 3 kW / 4 HP

-

Cutting length: min. 480 mm – max. 5050 mm

-

Angle adjustment: hydro-pneumatic at –22.5°, –45°, 90°, +45°

-

Positioning speed: 40 m/min

-

Air pressure: 6–8 bar / 100 L/min

-

Total power: 7.4 kW | 400 V | 50–60 Hz

-

Machine weight: approx. 1450 kg

Standard equipment

-

Two Ø 550 mm carbide-tipped saw blades

-

Pneumatic horizontal and vertical clamping cylinders

-

Servo-driven head positioning system

-

Spray cooling system for plastic profiles

-

Roller conveyor with movable cutting head

-

Digital display for angle and head positioning

-

CE-certified safety system

-

Hydro-pneumatic feed control for consistent cutting motion

Optional equipment

-

Barcode printer and cutting optimization software

-

Ethernet / USB data connection

-

Connection for chip extraction system

-

Automatic cutting optimization program

Performance, Stability, and Efficiency in Plastic Profile Cutting

The EVOG VSA Double Miter Saw is engineered for maximum productivity and continuous operation.

Both cutting heads operate in synchronization, drastically reducing cycle times — ideal for industrial window and door manufacturing.

Its hydro-pneumatic feed system ensures smooth blade movement, preventing material melting and maintaining dimensional accuracy.

The result is perfectly clean, vibration-free, and angle-precise cuts, requiring no additional finishing or trimming.

Advantages of the EVOG VSA Double Miter Saw for Plastic

1. Unmatched Cutting Precision

The servo-driven positioning system and digital angle adjustment deliver repeatable miter cuts with minimal tolerance, even on intricate profile shapes.

2. Large Cutting Capacity

With a cutting range of up to 5050 mm and angle settings down to –22.5°, the EVOG VSA easily handles large frames, long PVC profiles, and complex cutting geometries.

3. Industrial-Grade Durability

The rigid cast-steel machine base ensures vibration-free operation and extended service life, while high-quality drive components require minimal maintenance.

4. Energy Efficiency and Safety

The EVOG VSA operates with modern drive technology and a low-consumption hydraulic system, fully CE-certified for safety and reliability in industrial environments.

5. Intuitive Operation

With an ergonomic control interface, automatic head movement, and digital angle readout, the EVOG VSA offers user-friendly handling and consistent results in every production cycle.

Application Areas

The Double Miter Saw for Plastic Profiles EVOG VSA is suitable for a wide range of industrial applications:

-

Window production: precise cutting of PVC frames and sash profiles

-

Door manufacturing: accurate 45° and 90° miter cuts for door frames

-

Façade systems: clean, high-precision cuts for plastic or hybrid profiles

-

Industrial plastic processing: ideal for PVC, ABS, acrylic, polycarbonate, and other engineered materials

Thanks to its automatic control system, repeatable accuracy, and robust construction, the EVOG VSA is perfectly suited for both industrial production lines and specialized manufacturing workshops.

Operating Principle

During operation, profiles are automatically positioned between the two cutting heads and clamped pneumatically.

The servo-controlled system precisely adjusts both heads to the selected angle, while the hydro-pneumatic feed mechanism drives the blades smoothly through the material.

The integrated spray cooling system prevents melting and deformation of plastics, guaranteeing burr-free, smooth cut surfaces.

Each component is engineered for reliability and continuous operation with minimal waste.

Quality, Safety, and Reliability

Every EVOG VSA Double Miter Saw for Plastic Profiles is manufactured under strict European CE standards and undergoes comprehensive electrical, mechanical, and safety testing.

Evomatec ensures industrial precision, long-term stability, and reliable quality through advanced manufacturing and inspection processes.

The result is a machine that meets the highest global standards in performance, safety, and energy efficiency.

Future-Proof Technology and Economic Efficiency

The EVOG VSA is fully prepared for Industry 4.0 integration.

Its digital control interface, Ethernet/USB connectivity, and energy-saving drive system allow for easy connection to automated production lines.

With built-in options for cutting optimization, real-time data tracking, and multi-machine networking, it delivers measurable gains in productivity and profitability.

This makes the EVOG VSA a sustainable, long-term investment for modern manufacturers focused on growth, efficiency, and precision.

Conclusion – Precision, Efficiency, and Industrial Power

The Double Miter Saw for Plastic Profiles EVOG VSA combines cutting-edge automation, industrial-grade durability, and superior cutting accuracy.

With servo-driven positioning, hydro-pneumatic control, and a robust steel frame, it is the ideal choice for manufacturers who value quality, productivity, and efficiency in plastic and PVC profile fabrication.

Contact our sales team: info@evomatec.de

Request your free consultation at https://evomatec.de/en/contact/

TAGS

- double miter saw plastic

- double miter saw PVC

- automatic double miter saw plastic

- servo controlled double miter saw PVC

- hydro pneumatic double miter saw plastic

- miter saw for plastic profiles

- precision miter saw PVC

- window production double miter saw plastic

- CE certified double miter saw plastic profiles

- Evomatec double miter saw plastic

- profile cutting PVC windows

- door frame miter saw plastic

- automatic miter saw plastic profiles

- industrial miter saw PVC

- CNC double miter saw plastic

- hydraulic double miter saw PVC

- Evog VSA double miter saw plastic

- plastic profile miter cutting machine

- profile double miter saw PVC

- window profile double miter saw plastic

GERMANY

GERMANY ENGLISH

ENGLISH FRANCE

FRANCE SPAIN

SPAIN PORTUGAL

PORTUGAL