-

Company

Product

ALUMINIUM MACHINES

PORTABLE ALUMINIUM PROFILE MITRE SAW TOOL

PORTABLE COPY ROUTER MACHINE FOR ALUMINIUM PROFILES

PORTABLE END MILLING MACHINE FOR ALUMINIUM PROFILES

MITER SAW FOR ALUMINIUM PROFILES

COPY ROUTER MACHINE

END MILLING MACHINE FOR ALUMINIUM PROFILES

AUTOMATIC HYDRAULIC ALUMINIUM PROFILE CORNER CRIMPING MACHINE

DOUBLE HEAD CUTTING MACHINE FOR ALUMINIUM PROFILES

CNC AUTOMATIC SAW MACHINE FOR ALUMINIUM PROFILES

CNC PROFILE MACHINING CENTRES

ALUMINIUM COMPOSITE PANEL PROCESSING MACHINES

NOTCHING SAW MACHINE

WEDGE CUT SAW AND CLEAT CUT SAW

PVC PLASTIC MACHINES

PVC PLASTIC PROFILE MITER SAW MACHINE

PORTABLE COPY ROUTER MACHINE FOR PVC PLASTIC PROFILES

PORTABLE END MILLING MACHINE FOR PVC PLASTIC PROFILES

MITER SAW MACHINE FOR CUTTING PVC PLASTIC PROFILES

COPY ROUTER MACHINE FOR PVC PLASTIC PROFILE

END MILLING MACHINE FOR PVC PLASTIC PROFILES

PVC PLASTIC WELDING MACHINE

CORNER CLEANING MACHINE FOR PVC PLASTIC PROFILES

DOUBLE HEAD CUTTİNG MACHINE FOR PVC PLASTIC PROFILES

PROFILE MACHINING CENTRES

GLASS BEAD SAW

PRECISION MITER SAW FOR PLASTIC PROFILES

METAL MACHINES

MANUAL METAL SHEET BENDING MACHINE

MANUAL BENDING MACHINE

HYDRAULIC BENDING MACHINES

NON MANDREL BENDERS

PLATE BENDING MACHINES

BORDERING AND TRIMMING MACHINES

HORIZONTAL PRESSES

BELT GRINDING MACHINES

PIPE NOTCHING MACHINES

PIPE POLISHING MACHINES

LASER CUTTING MACHINES

CNC HYDRAULIC PRESS BRAKES MACHINE

CNC VERTICAL TURNING CENTER

CNC MACHINING CENTER

WOOD MACHINES

GLASS MACHINES

ROBOTICS SPECIAL MACHINERY

Service

Blog

Contact

product

- Home

- product

- PVC PLASTIC MACHINES

- PVC PLASTIC PROFILE MITER SAW MACHINE

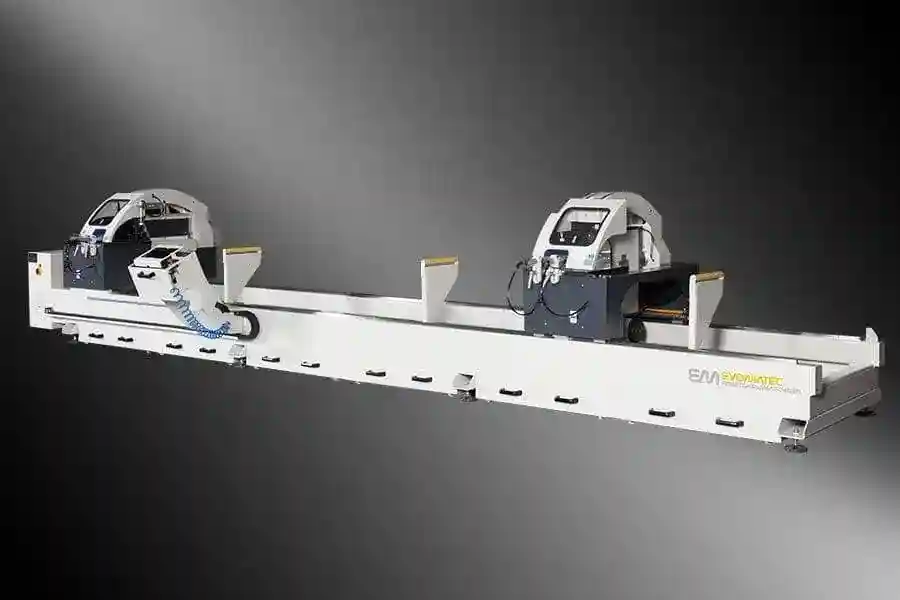

- RADİAL DOUBLE HEAD CUTTİNG MACHİNE Ø 550 MM - AUTOMATİON WİTH 3 AXİS SERVO CONTROL EVOG X

Radial Double Head Cutting Machine Ø 550 mm - Automation with 3 Axis Servo Control

FEATURES

Used for cutting processes of aluminum, plastic and wooden profiles.

Hydro-Pneumatic cutting. Servo controlled rotation axis. Secure cutting by the cover equipped with a safety sensor. Automatic positioning at all degrees between 30° and 90° with servo motion systemIndustrial PC with Windows based touchscreen and easy to use practical interface. Remote access. Data transfer over remote network connection, Ethernet and USB. Batch processing and precision cutting. Ability to perform cutting automatically from the list or manually. Adjustable saw blade travel speed. Ability to control saw blade travel distance. Process programming and large memory. Automatic horizontal and vertical clamps. Batch profile slicing. Automatic size calculation for mold cutting. Automatic profile support unit. Ability to cut profiles longer than 6000 mm up to 8000 mm length with built-in conveyor.

STANDARD EQUIPMENTS

Ø 550 mm saw blade (2 pcs)

Cooling system

OPTIONAL EQUIPMENTS

Barcode printer

Digital adjustment of saw blade travel distance

Conveyor on fixed head

Vacuum cleaner for chips

GERMANY

GERMANY ENGLISH

ENGLISH FRANCE

FRANCE SPAIN

SPAIN PORTUGAL

PORTUGAL