-

Company

Product

ALUMINIUM MACHINES

PORTABLE ALUMINIUM PROFILE MITRE SAW TOOL

PORTABLE COPY ROUTER MACHINE FOR ALUMINIUM PROFILES

PORTABLE END MILLING MACHINE FOR ALUMINIUM PROFILES

MITER SAW FOR ALUMINIUM PROFILES

COPY ROUTER MACHINE

END MILLING MACHINE FOR ALUMINIUM PROFILES

AUTOMATIC HYDRAULIC ALUMINIUM PROFILE CORNER CRIMPING MACHINE

DOUBLE HEAD CUTTING MACHINE FOR ALUMINIUM PROFILES

CNC AUTOMATIC SAW MACHINE FOR ALUMINIUM PROFILES

CNC PROFILE MACHINING CENTRES

ALUMINIUM COMPOSITE PANEL PROCESSING MACHINES

NOTCHING SAW MACHINE

WEDGE CUT SAW AND CLEAT CUT SAW

PVC PLASTIC MACHINES

PVC PLASTIC PROFILE MITER SAW MACHINE

PORTABLE COPY ROUTER MACHINE FOR PVC PLASTIC PROFILES

PORTABLE END MILLING MACHINE FOR PVC PLASTIC PROFILES

MITER SAW MACHINE FOR CUTTING PVC PLASTIC PROFILES

COPY ROUTER MACHINE FOR PVC PLASTIC PROFILE

END MILLING MACHINE FOR PVC PLASTIC PROFILES

PVC PLASTIC WELDING MACHINE

CORNER CLEANING MACHINE FOR PVC PLASTIC PROFILES

DOUBLE HEAD CUTTİNG MACHINE FOR PVC PLASTIC PROFILES

PROFILE MACHINING CENTRES

GLASS BEAD SAW

PRECISION MITER SAW FOR PLASTIC PROFILES

METAL MACHINES

MANUAL METAL SHEET BENDING MACHINE

MANUAL BENDING MACHINE

HYDRAULIC BENDING MACHINES

NON MANDREL BENDERS

PLATE BENDING MACHINES

BORDERING AND TRIMMING MACHINES

HORIZONTAL PRESSES

BELT GRINDING MACHINES

PIPE NOTCHING MACHINES

PIPE POLISHING MACHINES

LASER CUTTING MACHINES

CNC HYDRAULIC PRESS BRAKES MACHINE

CNC VERTICAL TURNING CENTER

CNC MACHINING CENTER

WOOD MACHINES

GLASS MACHINES

ROBOTICS SPECIAL MACHINERY

Service

Blog

Contact

product

- Home

- product

- ALUMINIUM MACHINES

- PORTABLE ALUMINIUM PROFILE MITRE SAW TOOL

- CNC CUTTING CENTER EVOAI

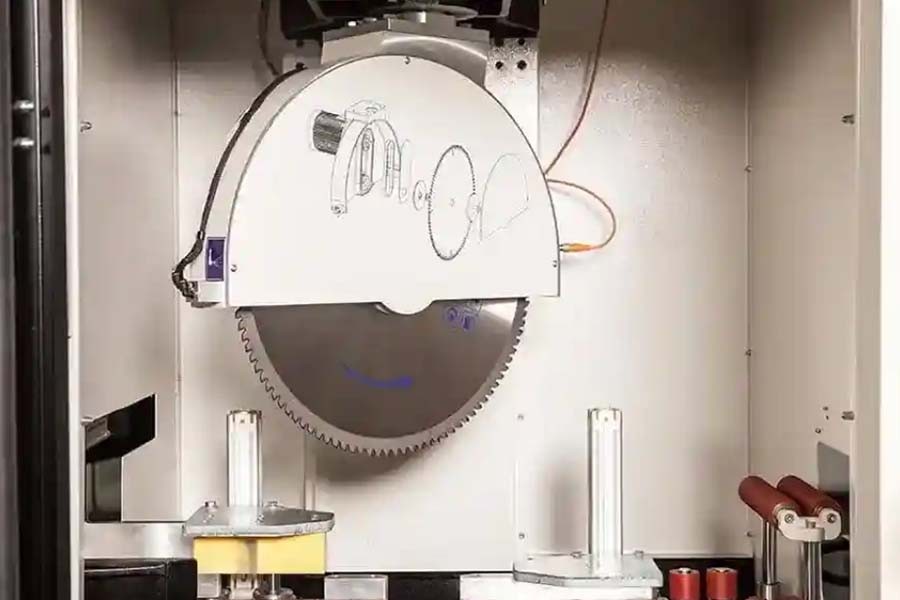

CNC-Controlled Profile Cutting Center (4-Axis) EVOAI

Features: The EVOAI is designed for cutting aluminum and PVC profiles with high precision.

Servo-controlled cutting for improved accuracy.

Servo-driven rotary axis with automatic positioning between 30° and 150° using a servo movement system.

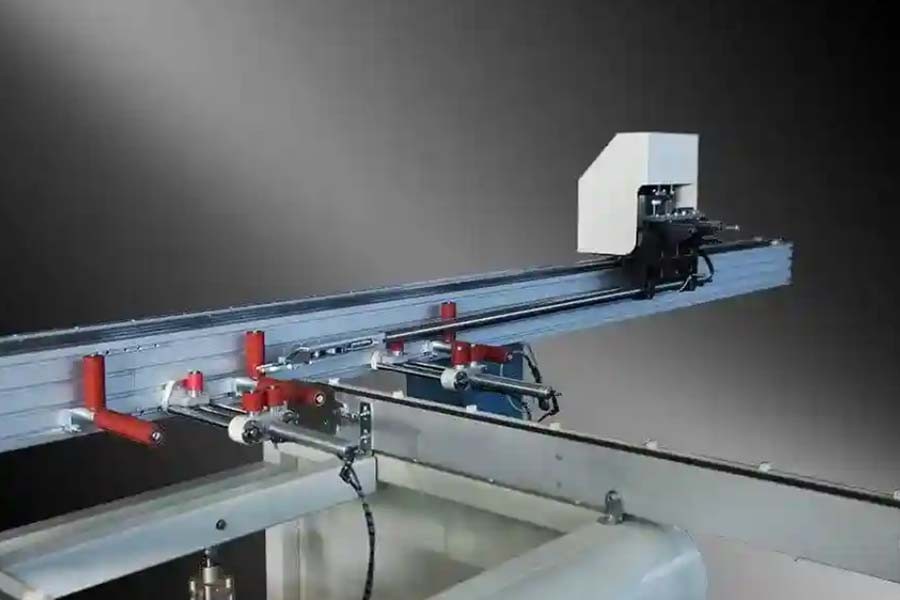

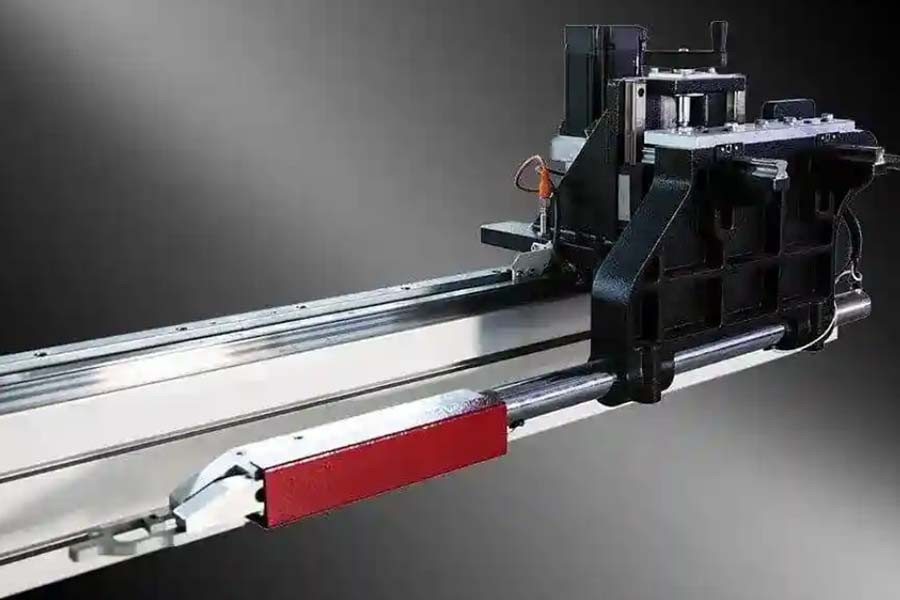

Pneumatic clamping robot with servo axis control and manual adjustment function for precise profile positioning.

Industrial PC with a Windows-based touchscreen interface for easy operation and remote access.

Data transmission via remote network connection, Ethernet, and USB.

Enhanced protection for the cutting area.

Process programming with a large memory for efficient operation.

Adjustable saw blade travel speed.

Option for automatic cutting from the list or manual operation.

Pneumatic conveyor system for profile unloading.

Cut advisory function in case of emergencies (e.g., power failure, emergency stop).

Profile list reading and recognition of uncut parts.

Barcode information transfer for various profile batches without the need for cutting optimization software.

Ability to select a profile from the list for batch cutting.

High-speed axis movements for improved efficiency.

Automatic lubrication in the processing area for maintenance-free operation.

Standard Equipment:

Ø 550 mm saw blade.

Automatic waste disposal unit.

Axis Travel:

Z2 Axis (cutting unit vertical movement): 260 mm.

XL Axis (robot drive): Min. 700 mm / Max. 7500 mm.

C2 Axis (cutting unit rotation): 120°.

Electrical:

Max. Power: 6.75 kW.

Frequency: 50-60 Hz.

Voltage: 400V 3N PE AC.

Positioning Speed:

Z2 Axis (cutting unit vertical movement): 42 m/min.

XL Axis (robot drive): 90 m/min.

C2 Axis (cutting unit rotation): 166°/sec.

Cutting Unit:

Cutting angle range: 30° / 150°.

Saw blade motor power: 3 kW - 4 HP.

Saw blade diameter: 550 mm.

Loading and Unloading Unit:

Minimum profile loading length: 700 mm.

Minimum profile unloading length (90° - 90°): 270 mm.

Maximum profile loading length: 7500 mm.

Profile loading capacity: 10 profiles.

Automatic chip discharge conveyor unit: Yes.

Control Unit:

Industrial PC - 15” Touchscreen.

Evomatec Machine Softcut software: Yes.

LS automation package: Yes.

Data transfer via remote network, Ethernet, and USB: Yes.

Barcode writer: Yes.

Compatibility with optimization programs: Yes.

FANUC automation package (optional).

Operational Area:

Automatic lubrication in processing area: Yes.

FESTO pneumatic system: Optional.

Guard cabin for cutting area: Yes.

Air tank: Optional.

Central automatic lubrication system: Optional.

Gripper Axis Travel:

YL Axis (Lateral): Min. 20 mm / Max. 150 mm.

ZL Axis (Vertical): Min. 20 mm / Max. 140 mm.

TAGS

- CNC Cutting Center

- CNC Cutting Machine for Aluminum Profiles

- PVC Profile Cutting Center

- Aluminum Profile Processing Center

- CNC Machine for PVC

- CNC Profile Processing

- Aluminum Profile Cutting

- PVC Profile Cutting

- CNC Cutting Machine Aluminum

- CNC PVC Cutting

- Aluminum Profile Cutting Machine

- CNC Machines for Aluminum Profiles

- CNC Milling for PVC

- Precise Profile Cutting

- Aluminum and PVC Cutting CNC

- Profile Processing Aluminum

- CNC Profile Cutting Center

- CNC Machines for Profile Cutting

- CNC Aluminum Cutting Machine

- CNC PVC Cutting Machine

GERMANY

GERMANY ENGLISH

ENGLISH FRANCE

FRANCE SPAIN

SPAIN PORTUGAL

PORTUGAL