-

Company

Product

ALUMINIUM MACHINES

PORTABLE MITER SAWS FOR ALUMINUM

PORTABLE COPY ROUTER MACHINES FOR ALUMINIUM

PORTABLE END MILLING MACHINES FOR ALUMINIUM

AUTOMATIC MITER SAWS FOR ALUMINIUM

COPY ROUTER MACHINES FOR ALUMINIUM

END MILLING MACHINES FOR ALUMINIUM

ALUMINUM CORNER CRIMPING MACHINE

DOUBLE MITRE SAWS FOR ALUMINIUM

AUTOMATIC SAWS FOR ALUMINIUM

BAR PROCESSING CENTERS

MACHINING CENTERS FOR ALUMINIUM COMPOSITE PANELS

NOTCHING SAWS

WEDGE CUTTING SAWS AND NOTCH CUTTING SAWS

MITER SAWS FOR ALUMINIUM

PVC PLASTIC MACHINES

PORTABLE MITER SAWS FOR PLASTIC

PORTABLE COPY ROUTER MACHINES FOR PLASTIC

PORTABLE END MILLING MACHINES FOR PLASTIC

MITER SAWS FOR PLASTIC

COPY ROUTERS FOR PLASTIC

END MILLING MACHINES FOR PLASTIC

WELDING MACHINES FOR PLASTIC

CORNER CLEANING MACHINES FOR PLASTIC PROFILES

DOUBLE MITRE SAWS FOR PLASTIC

BAR PROCESSING CENTERS

GLAZING BEAD SAWS

AUTOMATIC MITRE SAWS FOR PLASTIC

METAL MACHINES

MANUAL METAL SHEET BENDING MACHINE

MANUAL BENDING MACHINES

HYDRAULIC BENDING MACHINES

NON MANDREL BENDERS

PLATE BENDING MACHINES

BORDERING AND TRIMMING MACHINES

HORIZONTAL PRESSES

BELT GRINDING MACHINES

PIPE NOTCHING MACHINES

PIPE POLISHING MACHINES

LASER CUTTING MACHINES

PRESS BRAKES

VERTICAL TURNING CENTERS

MACHINING CENTERS

WOOD MACHINES

GLASS MACHINES

ROBOTICS SPECIAL MACHINERY

Service

Blog

Contact

Blog

- Home

- Blog

- PVC WINDOW MACHINE

- PVC WINDOW WELDING MACHINE

PVC WINDOW WELDING MACHINE

PVC Window Welding Machine: Technology, Applications, and the Future of Modern Window Manufacturing

The PVC window welding machine is the heart of modern plastic window production. It enables the precise and durable joining of PVC profiles into stable, airtight, and energy-efficient window frames. Without this technology, the efficiency, precision, and quality of today’s industrial window manufacturing would not be possible.

This in-depth professional article examines every aspect of PVC window welding machines – from technology and function to applications, investment, advantages, and future developments. It is written for engineers, manufacturers, and professionals involved in plastic window fabrication.

Thanks to our many years of experience from a wide range of customer projects, we can ensure that inspections are always carried out with the utmost precision, quality, and CE-compliant safety — a principle that has defined Evomatec’s engineering philosophy for years.

The Importance of PVC Window Welding Machines in Modern Construction

PVC windows have become a standard in the global building industry. They offer superior insulation, weather resistance, and a high cost-performance ratio. The quality of these windows depends largely on the welding process — the precision and durability of the corner joints.

A PVC window welding machine ensures that the window frame’s profiles are fused together under heat and pressure to form a homogeneous, inseparable, and airtight connection. The result is high stability, mechanical strength, and energy efficiency.

This technology is used across all segments of the window manufacturing industry — from small workshops to large-scale automated production lines.

Evomatec has long recognized this demand and developed welding systems focused on precision, durability, and CE-certified safety. Drawing on our extensive project experience, we ensure that every inspection and system test is carried out with the highest attention to quality and European safety standards.

Historical Development of PVC Welding Machines

From Manual Labor to Automated Precision

When plastic windows first appeared in the 1950s, profile welding was a fully manual process. Operators heated the profile ends using simple heating elements and pressed them together by hand — a slow, inconsistent, and skill-dependent method.

As demand increased throughout the 1970s and 1980s, pneumatic and hydraulic machines were introduced. They allowed better control of pressure and temperature, improving consistency and reducing labor intensity.

The CNC Revolution

In the 1990s, CNC technology completely transformed the industry. Machines could now automatically align profiles, maintain stable heating temperatures, and weld with repeatable accuracy. The introduction of data interfaces allowed several machines to operate in connected production lines.

Today, the PVC window welding machine is part of fully integrated manufacturing systems where cutting, welding, cleaning, and packaging are seamlessly linked.

With decades of experience and extensive engineering expertise, Evomatec ensures that every inspection and calibration is performed in full compliance with CE standards, guaranteeing precision, safety, and long-term reliability.

Technical Function and Welding Process

The welding of PVC profiles is based on thermal fusion — using controlled heat and pressure to soften and bond the profile surfaces. When cooled, the joint becomes a single homogeneous component with high strength and perfect airtightness.

Step-by-Step Welding Process

-

Profile Positioning – The pre-cut profiles are precisely clamped in place.

-

Heating Phase – A Teflon-coated heating plate, maintained at constant temperature, is placed between the profiles. The surface begins to melt evenly.

-

Joining Phase – Once the ideal temperature is reached, the heating plate is withdrawn and the profiles are pressed together under controlled force.

-

Cooling Phase – The welded joint remains under pressure while cooling to prevent deformation.

-

Release – The finished welded frame is removed from the machine.

The entire process takes between 20 and 60 seconds, depending on the profile size and machine type.

Key Factors for High-Quality Welding

-

Uniform temperature distribution (230–260 °C)

-

Controlled pressure and welding force

-

Accurate timing and temperature regulation

-

Clean, precisely cut profile surfaces

-

Consistent PVC composition

Modern CNC and PLC-controlled systems ensure perfect process consistency through digital monitoring and feedback control — a key feature in Industry 4.0 manufacturing.

At Evomatec, every welding system is built and tested under strict CE-compliant inspection procedures to ensure reliability and precision across the production line.

Construction and Main Components of a PVC Window Welding Machine

A modern PVC welding machine consists of the following key components:

-

Machine Frame: Solid welded steel design to minimize vibration and ensure precision.

-

Heating System: Teflon-coated heating plates with electronically controlled temperature.

-

Clamping Units: Pneumatic or hydraulic cylinders to hold profiles securely in position.

-

Control Unit: CNC or PLC-based control system for full automation and repeatability.

-

Cooling Section: Ensures proper solidification without distortion.

-

Safety Features: Protective guards, light barriers, and emergency stops per CE requirements.

-

Optional Corner Cleaning Units: Automatically remove welding beads for a clean visual finish.

This configuration guarantees precise, safe, and efficient manufacturing of PVC window frames.

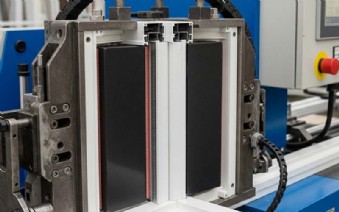

Types and Configurations of PVC Window Welding Machines

Single-Head Welding Machine

Compact and ideal for small workshops. Welds one corner per cycle, perfect for custom work or short production runs.

Double-Head Welding Machine

Welds two corners simultaneously, significantly improving efficiency.

Four-Head Welding Machine

Industry standard for high-volume manufacturing. All four corners of a frame are welded in one operation.

CNC Automatic Welding Lines

Fully automated systems with integrated profile feeding, parameter control, and data connectivity. Designed for continuous production and minimal operator intervention.

Seamless Welding Systems

Advanced machines capable of producing invisible, perfectly smooth corner joints for premium windows.

Advantages of PVC Window Welding Machines

-

High precision and repeatability through CNC control

-

Strong and durable joints without adhesives or fasteners

-

Energy efficiency through optimized heating systems

-

Productivity thanks to fast cycle times and automation

-

Aesthetic quality with clean, seamless welds

-

Low operating costs and long service life

-

CE-compliant safety for operators and systems

At Evomatec, each system is designed with these principles in mind. Regular inspections and quality tests ensure that all production units meet the strictest CE certification and quality assurance requirements.

Limitations and Challenges

While PVC welding machines are indispensable, they also come with some challenges:

-

Higher investment cost for advanced CNC equipment

-

Maintenance requirements such as heating plate cleaning and calibration

-

Operator training to ensure correct parameter setup

-

Material-specific adjustments since PVC compounds vary in formulation

However, with modern automation and digital control, these challenges are easily managed and outweighed by the benefits in precision and throughput.

Quality Assurance and CE Compliance

Every PVC window welding machine must comply with the European Machinery Directive and undergo strict CE certification.

Quality assurance includes:

-

Visual inspection of weld seams

-

Dimensional and angular accuracy tests

-

Strength and load testing

-

Documentation of all process parameters

Evomatec applies these standards rigorously. With extensive experience in industrial automation, we ensure that all inspections are conducted with maximum precision, safety, and full CE conformity.

Economic Efficiency and Return on Investment

A PVC window welding machine is a long-term investment that typically pays off quickly due to its efficiency and reliability.

Factors that Enhance Profitability

-

Reduced scrap and material waste

-

Lower energy consumption with optimized heating systems

-

Longer lifespan due to durable design

-

Reduced labor costs through automation

-

Consistent output quality with minimal downtime

With these advantages, a high-quality machine often pays for itself within a few years. For many manufacturers, transitioning to fully automated systems is a key factor in remaining competitive.

Future of PVC Welding Technology

The future of PVC window welding lies in digitalization, automation, and sustainability.

Industry 4.0 Integration

New machines are equipped with sensors and network interfaces to monitor all production parameters in real time.

Artificial Intelligence (AI)

AI-based control systems automatically adjust temperature, pressure, and cycle times based on live data, optimizing performance and minimizing human error.

Sustainable Manufacturing

Next-generation machines feature energy-efficient heating systems and recyclable materials, significantly reducing environmental impact.

Aesthetic and Seamless Design

Market demand continues to grow for seamless welding with invisible joints that meet the highest architectural and design standards.

Evomatec combines proven mechanical precision with digital innovation. With years of experience, we ensure that every inspection, update, and validation meets CE-certified safety and performance criteria.

Summary

The PVC window welding machine is the cornerstone of modern window production. It merges precision, productivity, and durability in one system, ensuring strong, airtight, and aesthetically refined window frames.

From compact single-head models to advanced CNC automation lines, the technology has evolved to meet the needs of both small workshops and large industrial plants.

Thanks to our long-term experience across numerous customer projects, we guarantee that every inspection, commissioning, and quality check is executed with the highest care and CE-compliant safety. Evomatec represents precision engineering, reliability, and sustainable innovation in the global window machinery industry.

FAQ – Frequently Asked Questions

1. How does a PVC window welding machine work?

It heats the ends of PVC profiles until they soften and then presses them together under defined pressure. After cooling, a permanent, airtight joint is formed.

2. What types of PVC welding machines are available?

There are single-head, double-head, four-head, and fully automated CNC models — each designed for different production scales.

3. How often should a welding machine be maintained?

Regular cleaning of heating plates and annual calibration are essential. A full CE inspection once per year is recommended.

4. How much does a PVC welding machine cost?

Prices vary depending on automation level and configuration, ranging from entry-level workshop units to industrial CNC systems.

5. Why is CE certification important?

It ensures that the machine meets European safety and quality standards, protecting both operators and manufacturers.

Free consultation available at www.evomatec.com

- PVC window welding machine

- PVC welding technology

- plastic window welder

- PVC profile welding machine

- hot plate welding PVC

- window frame welding machine

- CNC welding machine for windows

- seamless PVC welding system

- industrial PVC window production

- automated window welding line

- CE certified welding equipment

- window manufacturing technology

- quality control PVC welding

- investment window welding system

- process optimization PVC window fabrication

- Industry 4.0 window manufacturing

- plastic welding equipment for window frames

GERMANY

GERMANY ENGLISH

ENGLISH FRANCE

FRANCE SPAIN

SPAIN PORTUGAL

PORTUGAL